In ‘ Small-Scale Static Fire Tests of 3D Printing Hybrid Rocket Fuel Grains Produced from Different Materials ,’ authors Mitchell McFarland and Elsa Antunes create a device to evaluate small-scale fuel grains, focusing on material regression rates, as well as comparing them to other hybrid fuels in experiments that are important to the space industry as new rockets and motors are created, using a variety of technologies and new materials.

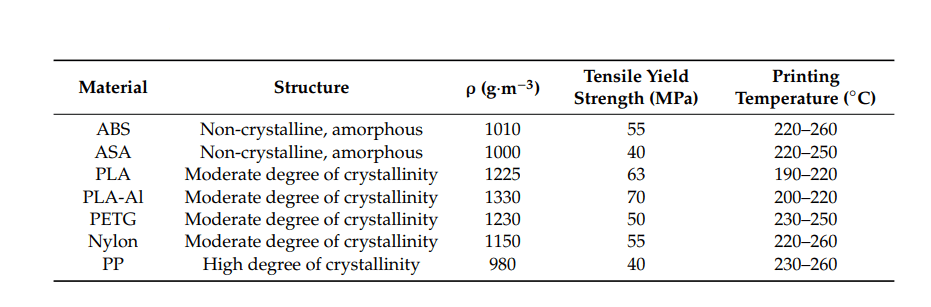

McFarland and Antunes explain that 3D printing has been the ‘most impressive advancement,’ and especially with FDM 3D printing as it offers all the benefits that are attractive to investors and manufacturers, from speed in production to substantial savings on the bottom line. “FDM has enabled designers to incorporate complex combustion ports into HRMs and has opened up an entirely new set of materials for the fabrication thereof,” state the researchers. Typical casting and curing techniques can be more […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments