Nano Dimension Ltd . has developed 3D printed capacitors with the Company’s pioneering DragonFly additive manufacturing system.

.

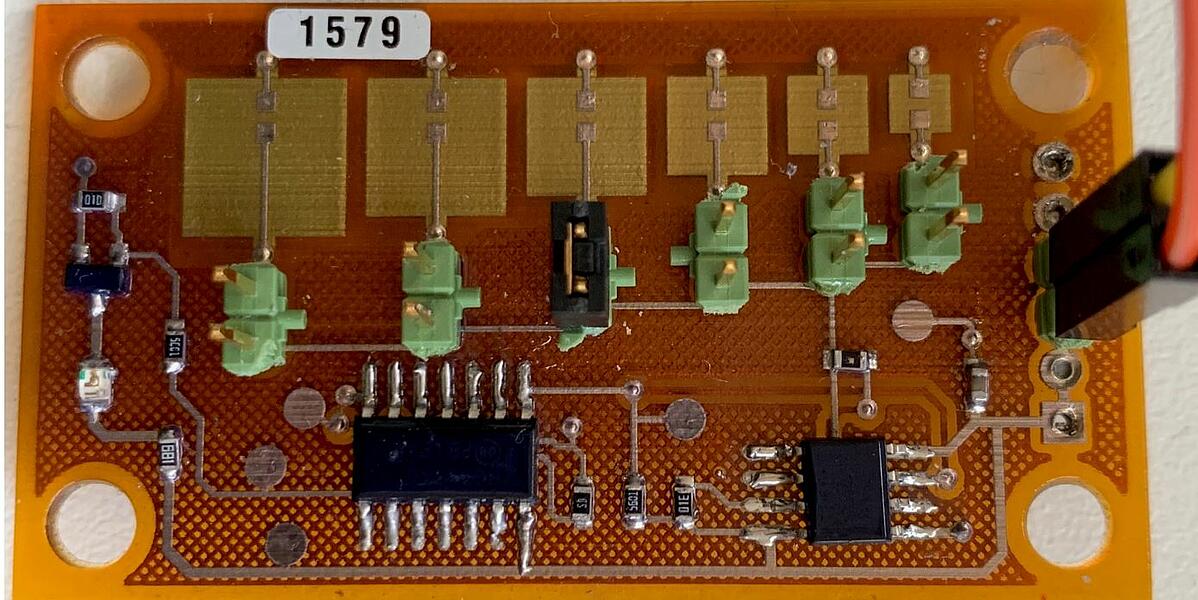

These capacitors are embedded in the body of the additively manufactured printed circuit boards (PCBs), saving space and eliminating the need for assembly. This breakthrough in the additive manufacturing of electronics validates the manufacturing applicability of built in capacitors in PCBs printed with the award-winning DragonFly system, the only precision additive manufacturing system of its type.

.

The image above shows a DragonFly-3D printed PCB with 6 capacitors and soldered components. Capacitors of this kind are primarily used to filter electrical noise and ripple voltage for a wide range of applications, including RF transmission lines, audio processing, radio reception and power circuit conditioning. Nano Dimension’s extensive testing with capacitors of different 3D dimensions have shown consistent results with statistically validated data. The repeatability results show less than 1% variance. The technology uses the […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments