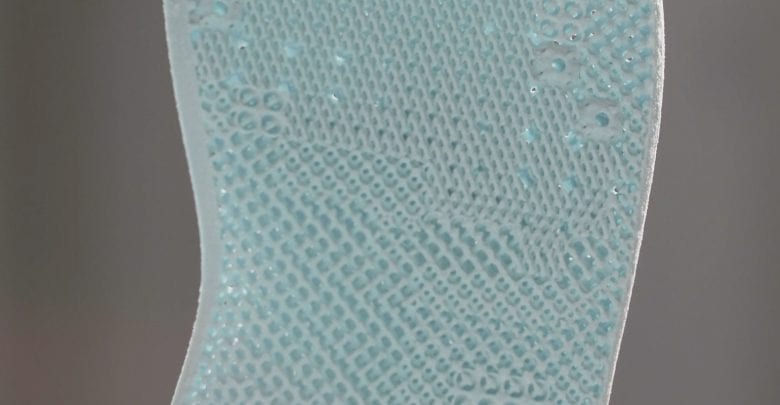

After nearly 80 years with minimal innovation, the foam industry is now employing 3D printing to produce products that are more comfortable, safer, lighter, and can be customized for each individual.

.

Now EOS North America and its Additive Minds applied engineering team launched their Digital Foam program – a hub orchestrated by EOS connecting CAD, materials, part qualification, and additive manufacturing.

.

In this hub, the complexity of bringing 3D printed foam to-market has now been simplified by giving customers a fast-track to producing 3D printed protective headgear, individualized orthotics, or performance footwear, among dozens of other applications.

.

Using highly flexible polymer materials, like TPU or PEBA, 3D printing foam allows unprecedented fine-tuning of each voxel for superior comfort, safety, and performance characteristics. The process is a sophisticated endeavor that historically requires complex engineering and long cycle times to fully unlock its value. “The level of engineering required to produce, […]

Click here to view original web page at www.3dprintingmedia.network

0 Comments