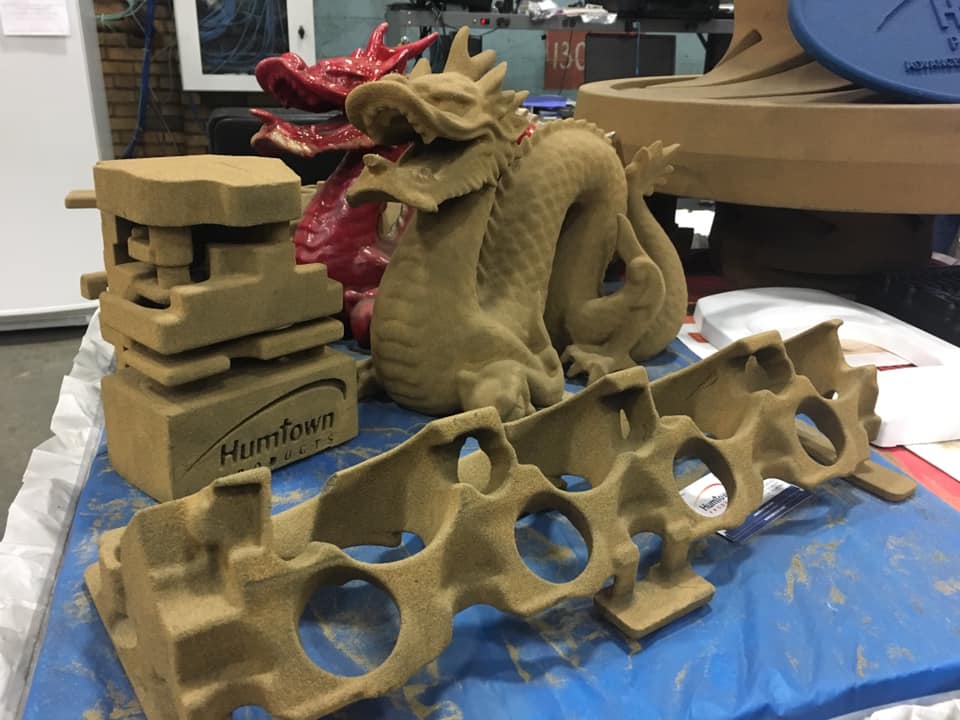

When you talk about 3D printing, using sand probably isn’t the first thing that pops into your mind. It’s a material Humtown Products in Leetonia’s used for decades, but now with this new technology it’s taking the company to new heights.

.

The world is now Mark Lamoncha’s sandbox at Humtown Products in Leetonia.

.

The business itself has been around since 1959; they’ve been making sand cores since 1977. Four years ago, the company began transitioning to 3D printing. “This is really the way that core making should have always been done,” said Lamoncha. The process wasn’t cheap, so he couldn’t make the leap all at once.

.

“In our traditional method it could be between two and three cents a cubic inch. This started out at 17 cents in the 3D sand printing, so I think it’s easy to see why it couldn’t grow very fast,” said Lamoncha. But once the cost came down, Humtown was all-in. .

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments