Metal Additive Manufacturing (AM) processes continue to improve in speed, cost, efficiency, and part quality. However, this trend is asymptotic. Metal AM technologies are ultimately constrained by the underlying laws of physics. Namely, the physics governing the movement of material and energy, and the dynamics of melting and solidification.

.

By studying the physics governing metal AM, we can better understand both the limitations and maximum potential of the specific AM processes.

.

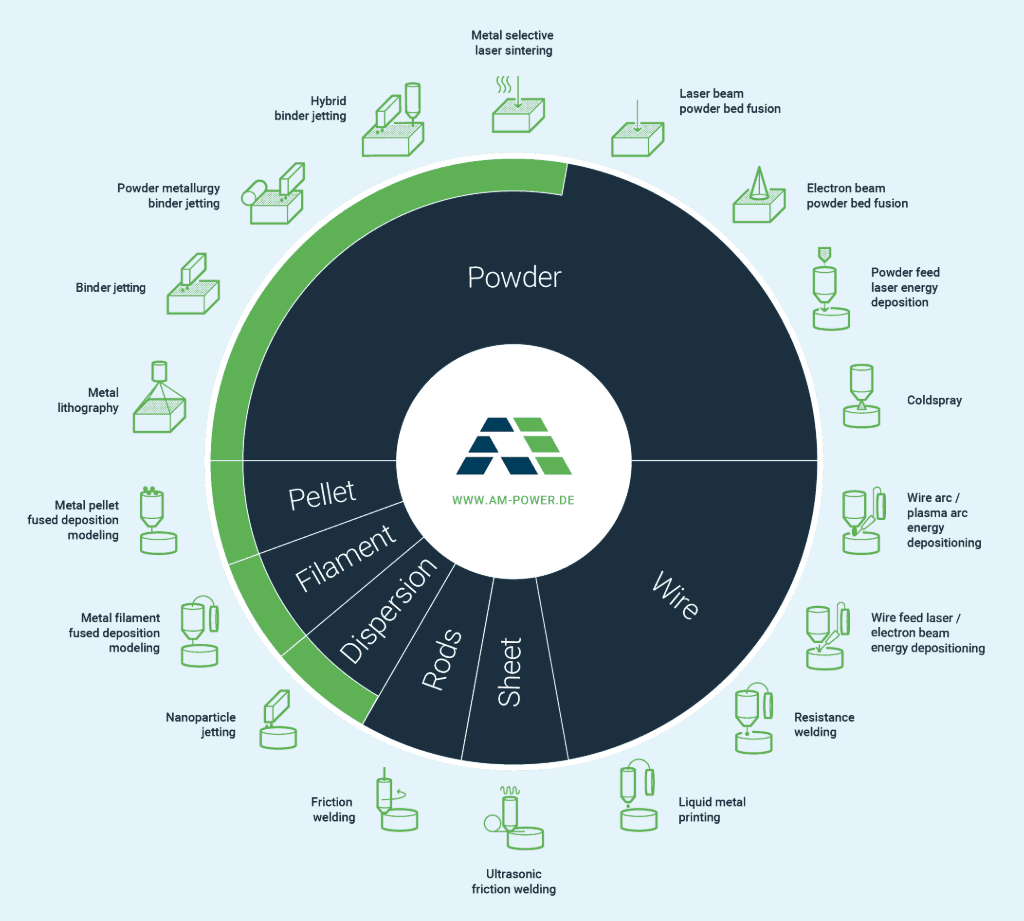

Manufacturing is the processing of raw material (feedstock) into finished goods. Material processing requires the movement of material and energy. In metal AM processes, the primary material input is powder or wire, and the primary energy input is electricity which is converted to heat.

.

We will focus on these four metal AM processes: .

Powder Bed Fusion (PBF): The most widely used metal printing process, in which metal powder is spread into a thin layer and then selectively melted with a laser or electron beam.

Binder Jetting: Metal powder is spread into a thin layer, selectively bound, and then heated in a furnace to remove the binder and sinter the metal.

Directed Energy Deposition (DED): Metal powder or wire is melted using a laser, electron beam, plasma, or electric arc; dripping or spraying molten metal onto the part.

Joule Printing™: Wire is positioned in contact with the part and resistive heating melts the wire right at the point of deposition.

.

Click here to view original web page at www.digitalalloys.com

0 Comments