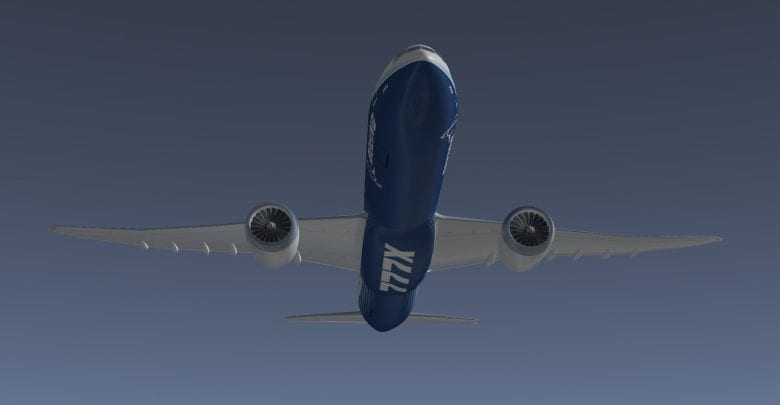

Additive manufacturing history is in the making today with the first flight of the Boeing 777x. That’s because each of the two GE9X engines powering the aircraft has almost 300 additive manufactured components.

.

These parts were produced by GE teams at Avio Aero in Cameri, Italy and GE’s Additive Technology Center in West Chester, Ohio. This tremendous achievement for Boeing and GE – which can be tracked live on the dedicated website – marks a very important advancement for flying parts made by additive manufacturing in aviation.

.

Based on the top-selling Boeing 777, which first went into service in 1994, and with advanced technologies from the Boeing 787 Dreamliner, the 777X will be the largest and most fuel-efficient twin-engine jet in the world. Featuring new breakthroughs in aerodynamics along with its engines, the 777X will deliver 10 percent lower fuel use and emissions and 10 percent lower operating […]

Click here to view original web page at www.3dprintingmedia.network

0 Comments