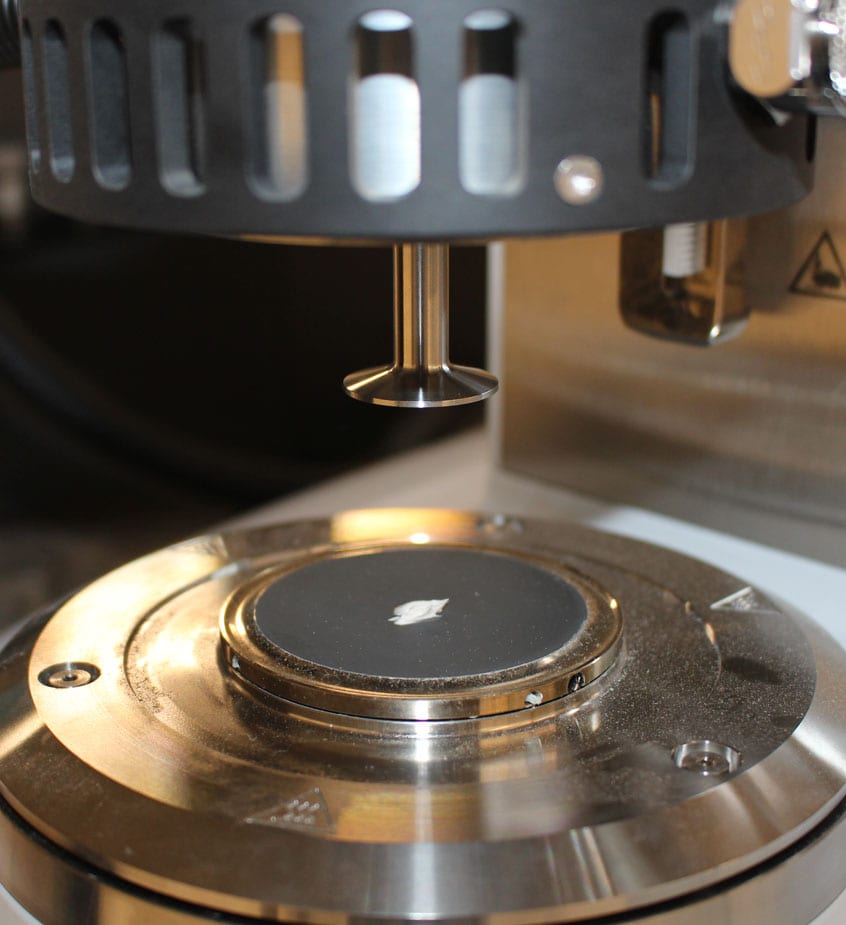

In a corner of the ground floor inside the Youngstown Business Incubator’s Tech Block Building 5 downtown, Gary Gladysz uses a rheometer to test a small sample of a white, pasty substance.

.

The substance is an initial formulation of his 3D printer ink. A small dab sits on a plate attached to the device, which uses a cylinder to press down and twist the ink, measuring how much torque is required to manipulate the ink. This measures its viscosity, Gladysz says.

.

“Since we’re not curing on the part bed, we need a real thick paste so when you put layer upon layer it doesn’t collapse,” he says. “You want as viscous as possible. But when you’re pumping it, you want that viscosity to drop.” Unlike traditional thermoplastic 3D printing filament, which requires a heated print head and print bed to cure the part as it prints, […]

Click here to view original web page at businessjournaldaily.com

0 Comments