If you would’ve visited Able Tool before 2003, you never would’ve pegged the Cincinnati-area machine shop as one actively investing in the latest manufacturing technology. Back then, a quick glance around the shop would show mostly toolroom-style equipment.

However, that began to change when Paul Hayes took over as company president. For the business to thrive, he knew the operation would have to take a quantum leap by adopting much more advanced technology.

Today, Able Tool’s shop floor consists of four- and five-axis machining centers and large horizontals and wire EDM. On-machine spindle and tool probes have reduced setup time on that equipment and enables in-process inspection for more effective process control. The company’s commitment to adopting new technology didn’t end there. About six […]

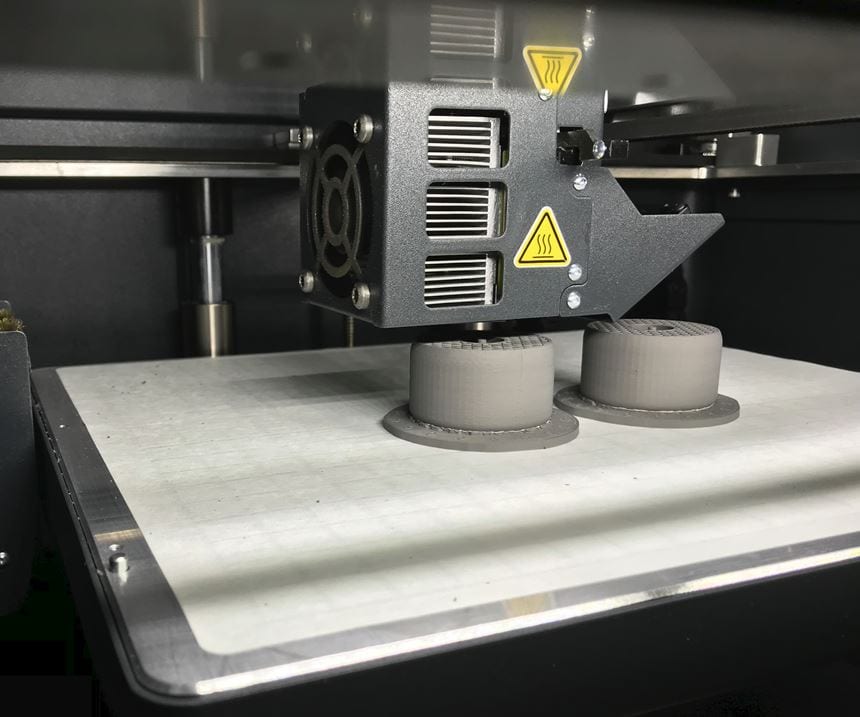

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments