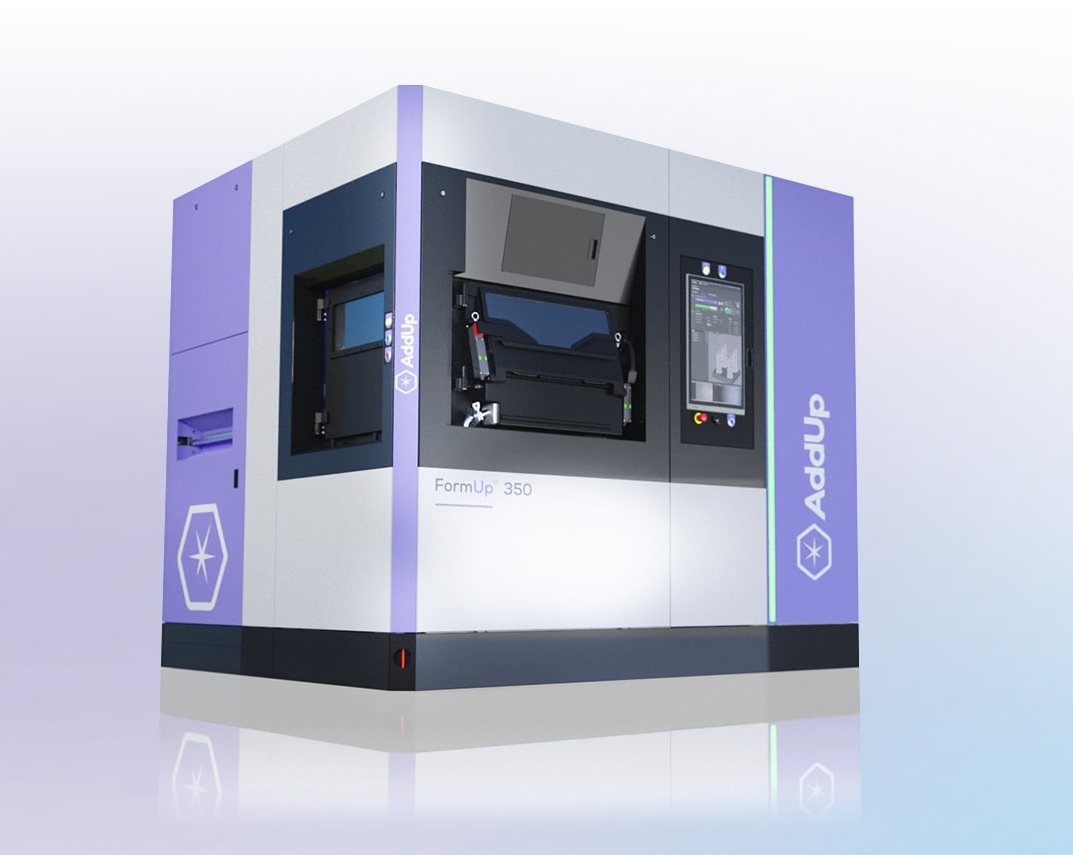

AddUp, a joint venture created by Michelin and Fives in 2016, has announced the introduction of FormUp®350 metal 3D printer – a laser powder bed fusion (L-PBF) technology.

.

The FormUp 350 allows to operate in complete safety, to produce perfectly reproducible series of parts at levels of productivity never achieved before, by relying on a modular and scalable architecture. FormUp 350 delays the machine obsolescence and keep up a high level of performance. FormUp 350 Metal 3D Printer Above:

.

Solutions Lasers The new generation of FormUp 350 metal 3D printer can produce parts using four 500 W lasers simultaneously, each laser covering the entire surface of the tray. The bidirectional coating system reduces non-productive times by 40% faster powder spreading cycles than mono-directional spreading. The powder supply is done in masked time, using the autonomous powder module mentioned above. Applications Specific manufacturing recipes can be developed for each application, to find the best balance between productivity and quality for each part. AddUp provides support to our customers with a unique application service on the market, based on the […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments