French metal 3D printing group AddUp has entered into a $2.7 million agreement with the U.S. Department of Energy’s Oak Ridge National Laboratory (ORNL) to push laser powder bed fusion (PBF) for the use of 3D printing metal molds.

.

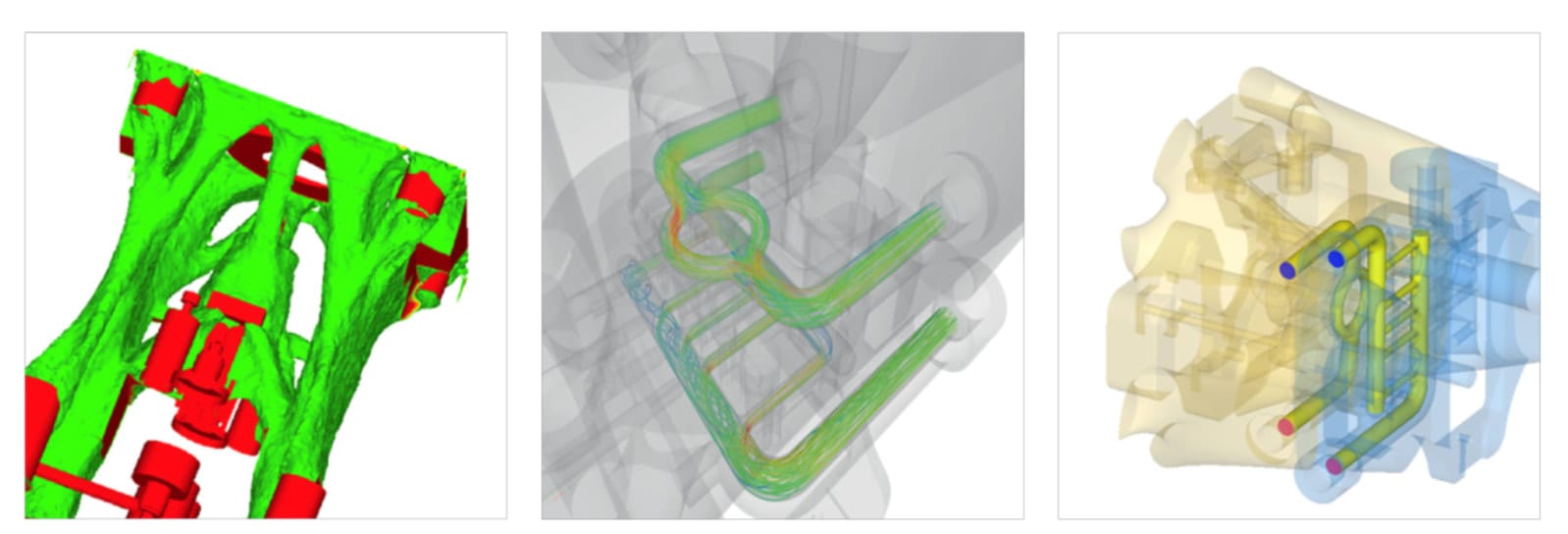

While additive manufacturing (AM) is regularly used for the production of tooling, the metal mold supply chain has yet to be truly disrupted by the technology. Given its history of making millions of parts within (its part-owner) Michelin’s own tire mold fabrication process, AddUp may be an important actor in this disruption.

.

The AddUp Group is the result of years of research on the behalf of Michelin to create better, more cost-effective tires. Since 2000, the company began exploring the possibilities of AM for making tire molds, ultimately leading the development of in-house metal 3D printers. Michelin has roughly two dozen such systems installed worldwide 3D printing over a million […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments