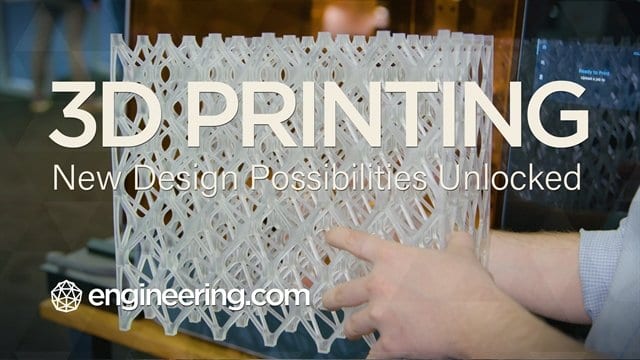

In this video, we’ll examine how the capabilities of additive manufacturing extend beyond design and change potentially the entire way we think about designing, making and bringing to market products in a broad range of industries, including consumer goods, aerospace, and automotive.

.

Conventionally, we tend to think of a cost-effective design as one that uses basic shapes, maybe even one that’s literally fabricated from basic stock shapes such as sheet and tube. In subtractively manufactured parts, which are parts machined or formed via a machined mold or tool, design features are decided by compromise.

.

But what if we didn’t need to make these compromises?

.

Check out the video to see additive manufacturing experts from across the industry weigh in on these opportunities. If the design freedom and other advantages of additive manufacturing technology create opportunities for higher quality and lower cost elsewhere in the product lifecycle, additive manufacturing machines […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments