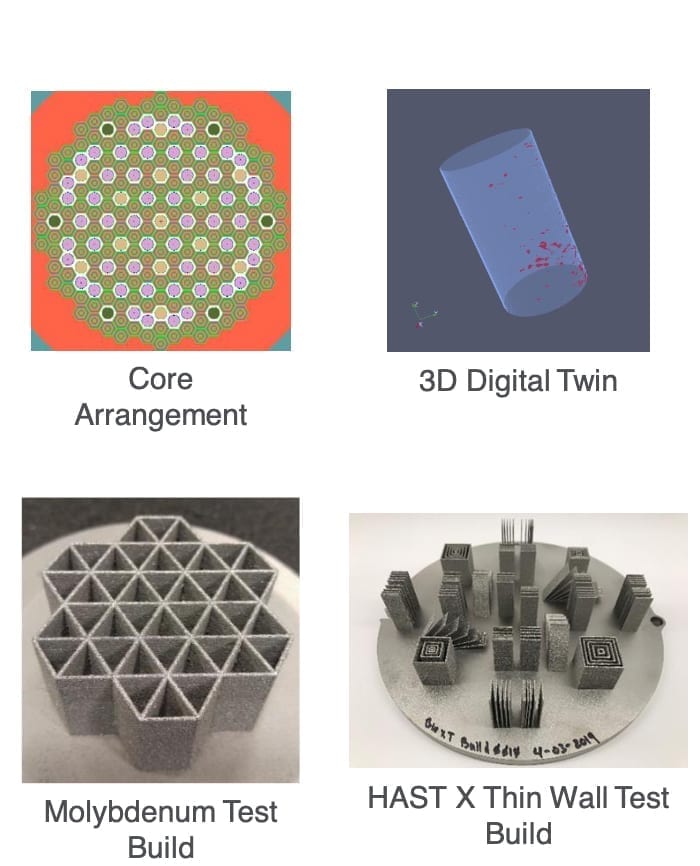

News BWX Technologies (BWXT) on Nov. 23 said it has demonstrated the ability to additively manufacture nickel-based super alloys and refractory-metal-based alloys for use in nuclear components. The company also said it has “accomplished component-level qualification, leading to a more efficient certification of nuclear materials configured in complex geometries.”

.

The 3D printing breakthroughs achieved through a collaboration with Oak Ridge National Laboratory (ORNL) could help speed up development of advanced nuclear reactors, which are often designed to operate at very high temperatures. Refractory metal alloy-based core components are thought to enable advanced reactors to reach core exit temperatures of 2,700F and overall plant efficiencies of approximately 50%. But the breakthroughs also promise to improve efficiencies for the current commercial nuclear fleet, which have made notable headway in testing accident-tolerant fuel designs . 3D Printing Reshaping High-Temperature Component Manufacturing “Additive manufacturing technologies will be transformational for the nuclear industry because […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments