After more than 30 years in the additive manufacturing (AM) market , its founder Hans Langer having shaped much of today’s laser-based AM industry and a line-up of industrial 3D printers adopted everywhere from companies like Morf3D or Shapeways to medical device manufacturers like Smith & Nephew and Zimmer/ Biomet , EOS knows a thing or two about what you should expect from your metal AM system.

.

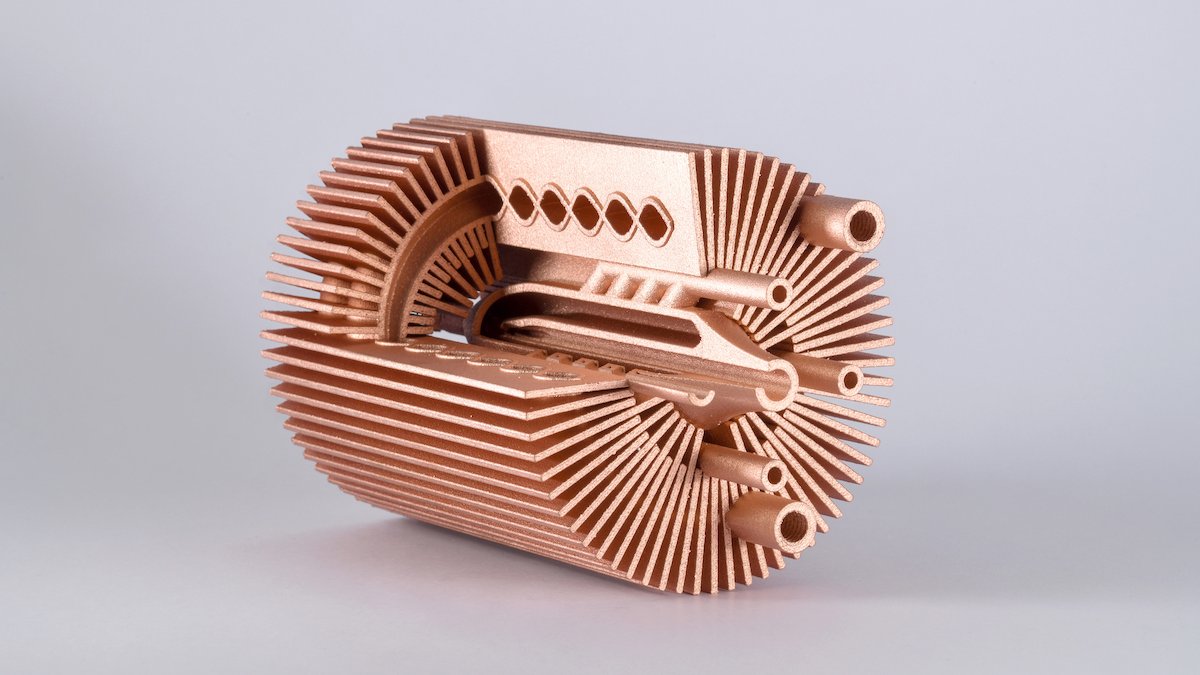

When it comes to production, the Direct Metal Laser Solidification (DMLS) pioneer believes productivity, reliability and repeatability are the ‘holy trinity’ of features that ought to be at the top of your machine buying checklist. In recent years, attention has shifted away from cost-per-part towards productivity; fast build speeds, maximising machine uptime, high utilisation rates and reducing the time spent on non- productive tasks such as setup and recoating. Bucking the current trend to boost efficiency by adding more lasers, EOS recommends concentrating on the versatility of the lasers you already have. Do they cover the entire build area? Can they be adjusted for your production needs? Is the build platform large enough to handle a range of part sizes and rotational symmetric production? The four precision fiber lasers inside the EOS […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments