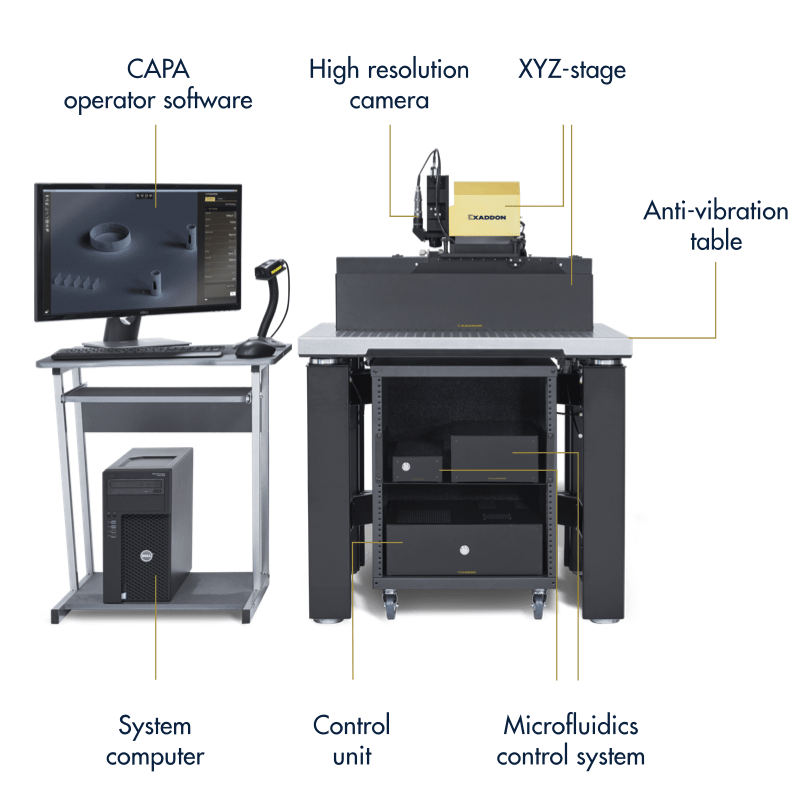

The CERES system, developed by Exaddon AG, directly 3D prints metal under ambient conditions.

.

The system builds complex structures with submicron resolution by additive manufacturing, opening new horizons in domains such as microelectronics, MEMS and surface functionalization.

.

The metal printing process is voxel based. Voxels are defined as elementary 3D blocks. Stacked in a layer-by-layer sequence at defined coordinates, the voxels form the desired 2D or 3D geometry.

.

Free-standing structures and 90° overhanging angles are feasible without support structures, bringing true design freedom. CERES – 3D printing system – key facts: Printing volume of metal up to 6’000’000 µm3 Chamber volume 100 x 70 x 60 mm Process speed up to 200 µm/s Positioning jitter XY ±10 nm & Z ±3 nm

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments