The manufacturing startup Divergent 3D is looking to expand the use of 3D printing technology to reduce the cost of designing, producing, and fully assembling vehicles while going green at the same time.

.

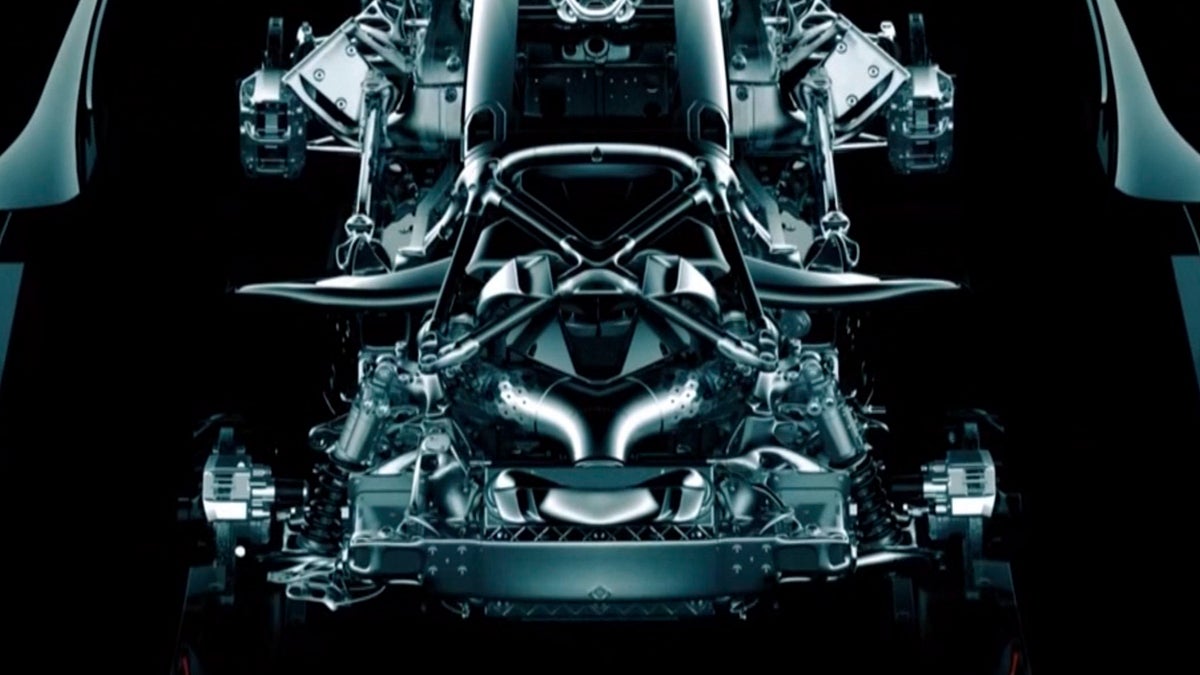

Kevin Czinger, CEO and lead inventor at the company, declared that the use of printing will slash production expenses for major automotive companies and create more efficient vehicles. “By doing what we’re doing, we’re massively lowering that cost of entry and giving people, say like AWS [Amazon Web Services] gives people access to tools and processing power and storage, we’re doing the same thing with design tools and production and assembly capacity,” he told Cheddar. The technology is able to convert powdered metal into car frames, suspensions, and subframes by heating it to nearly the melting point, then shaping it with a low powered laser. The company created the world’s first 3D printed car, the Divergent Blade, back in 2015 and this year, the Czinger 21c made its debut. Beyond lowering costs, the draw for 3D printing automobiles, according to the CEO, is the ability to produce various types of structures simultaneously as well as having a lower carbon footprint. “If you really look at the […]

The Intersection of Drones and Additive Manufacturing

SHAPEWAYS.COM 2 This eBook is for designers engaged at the intermediate and advanced 3D printing levels, offering...

0 Comments