While covering the global additive manufacturing industry, we occasionally run into startup companies working on technologies that may seem marginal but have a huge potential. It’s not just about having a good idea, as much as about finding true manufacturing pain points—which is not nearly as easy as it sounds—and, more importantly, having the know-how to address them.

.

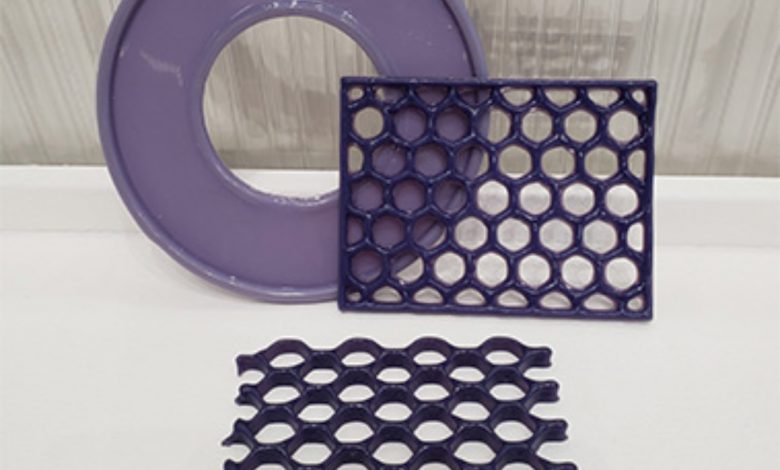

Chromatic 3D Materials ‘ work with extrusion of thermosets, polyurethanes in particular, is a perfect example. The ability to proficiently, and cost-effectively, 3D print one of the world’s most used materials will open an enormous opportunity.

.

And one of the best parts of C3DM’s approach is that this opportunity could be exploited by every one of the many extrusion 3D printer manufacturers around the world.

.

The company’s approach is materials- and software-based, and hardware agnostic. Chromatic 3D Materials’ FlexTune™ 3D Printed Polyurethanes are a range of rubber elastomers that offer both high-performance and high flexibility, with almost endless potential applications, from automotive to consumer products. CEO Cora Leibig founded the company back in 2016, building on a 20-year career in the materials industry. At Dow Chemical she worked in corporate R&D and polyurethanes-specific R&D for a decade. “For a new technology […]

Click here to view original web page at www.3dprintingmedia.network

0 Comments