The recent collaboration between Fiat Chrysler Automobiles (FCA) and Fraunhofer Research Institution for Additive Manufacturing Technologies IAPT began simply enough: with all of the advances in 3D printing, would it be possible to manufacture the entire suspension system using additive manufacturing alone?

.

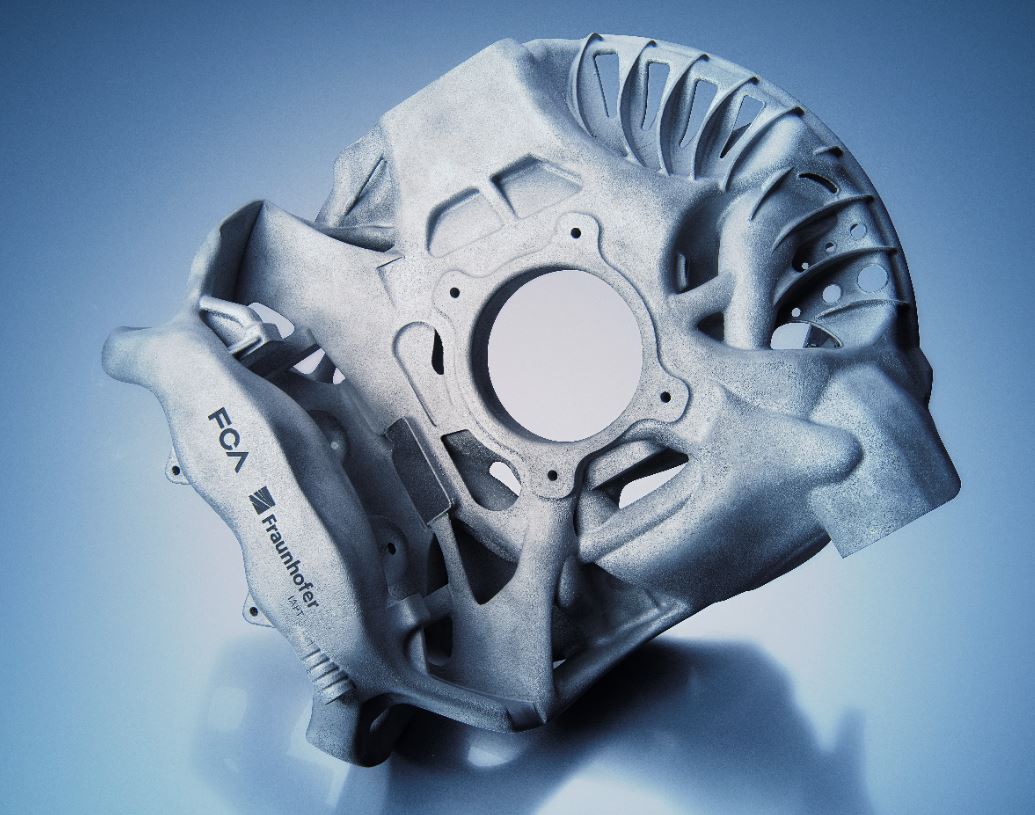

In the end, the answer was a remarkable, first-of-its-kind additively manufactured wheel carrier, with an integrated brake caliper, that can be implemented into series production for luxury and sports cars. The eye-catching, wheel carrier with integrated brake caliper, manufactured as one piece using AM.

.

Typically, suspension systems are an assembly of several critical components, including the brake caliper, wheel carrier, hydraulics, heat shield etc., held together by screws, seals and washers, all made through a complex, multi-step, time-consuming process. In this case, the suspension part was originally made up of 12 components. By using AM, the part assembly was consolidated as one-piece and […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments