Much remains unknown about how exactly Ford plans to fast-track production of ventilators and powered air-purifying respirators with two established medical device makers as it hurries to join the fight against the expanding coronavirus outbreak. But it’s likely that the automaker will leverage its decades spent tinkering with 3D printing.

.

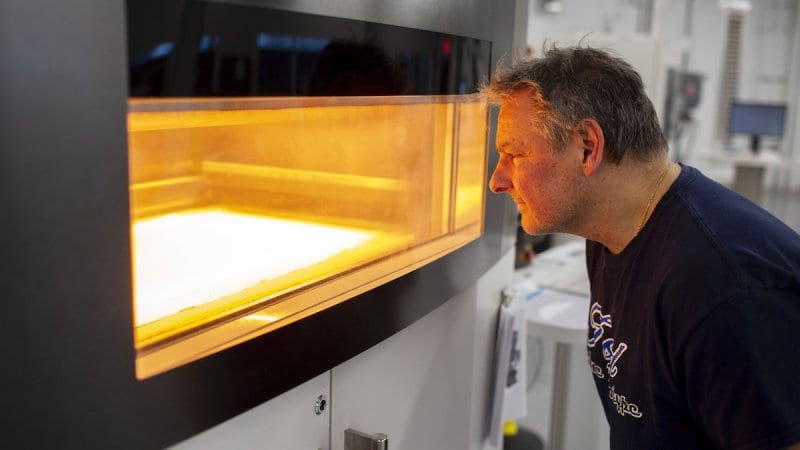

In its announcement Tuesday , Ford made it clear that the technology is central to its plans to assemble more than 100,000 protective plastic face shield masks per week from a subsidiary in suburban Detroit. The company also said it would use 3D printing at its Advanced Manufacturing Center in Redford, Mich., to make components and sub-assemblies for use in personal protective equipment. Ford opened the $45 million facility in 2018; at the time, it said it had 23 3D printers and was working with 10 3D printing companies. Included in Tuesday’s announcement was a plan to partner with […]

A Perfect Pair: 3D Printed Drones

Drones bring great energy to the design and 3D printing realm, with engineers engaged in developing new technology...

0 Comments