To produce brake calipers for its Chiron supercar, Bugatti embraced additive manufacturing, creating the largest titanium 3D printed component yet.

Because titanium is so strong, it’s impossible to use the same milling and forging technology used to form traditional aluminum calipers, Popular Science reported . Instead, the part is produced from 2,213 layers of titanium powder melted by lasers for over 45 hours and then heat-treated to 1,300 degrees.

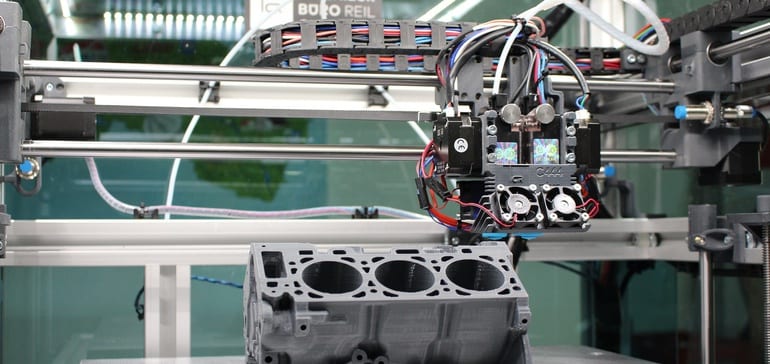

The part undergoes 11 hours of grinding to ensure each component meets exacting tolerances. With rapid e-commerce growth, supply chain professionals are overwhelmed. Wearable augmented reality (AR) solutions can help. Learn how in our playbook. Download Now Manufacturers from Bugatti to Boeing to BMW have invested in additive manufacturing, or 3D printing, in which objects are created by layering plastic or metal — as opposed to traditional subtractive manufacturing in which material is removed to create an […]

Click here to view original web page at www.supplychaindive.com

0 Comments