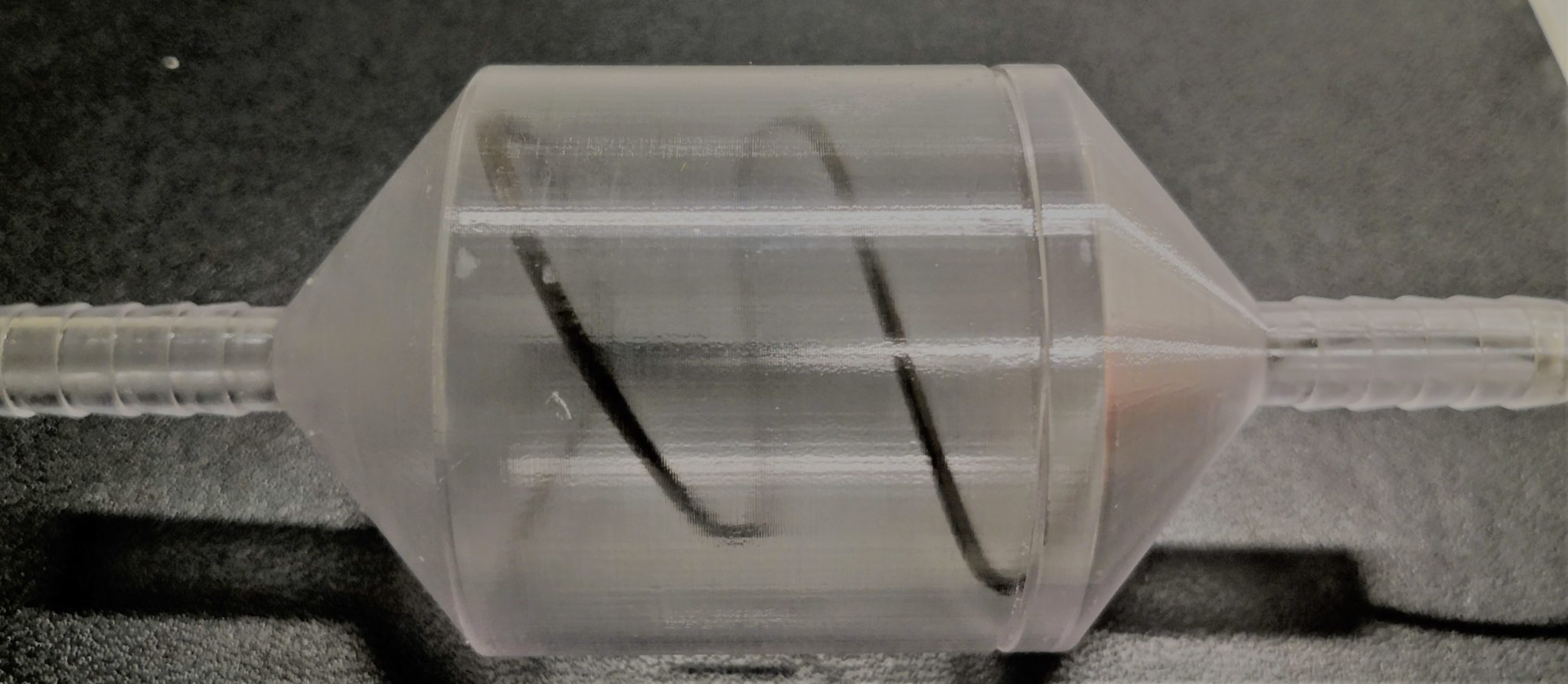

Testing thrombogenicity of a heart valve has always required an in vivo assessment. The in vitro blood loop offers a less expensive, faster option of thrombogenicity testing for valves through the use of custom 3D-printed chambers.

.

Many specialty medical devices, such as mapping catheters, large-vessel stent grafts, intravascular pumps (LVADS), endovascular grafts and artificial valves are destined for deployment within the patient’s vasculature in a flowing blood path. Device regulators need to be assured that neither the surface characteristics nor the device materials could cause inappropriate interactions with blood. Therefore, a critical part of the regulatory submission for market approval of these devices will be an assessment of thrombogenicity — assessing for surface- or materials-mediated activation of circulating platelets or components of the blood-clotting cascade that may result in thrombus formation and pose a risk to patient safety.

.

Although these complex and bulky devices may be single-use, such as a mapping catheter, or permanent implantables such as stent grafts or valves, the hemocompatibility testing in all cases will require a stringent assessment of thrombogenicity as stipulated in Table 1 of ISO 10993-4 Biological evaluation of medical devices – […]

Click here to view original web page at www.medicaldesignandoutsourcing.com

0 Comments