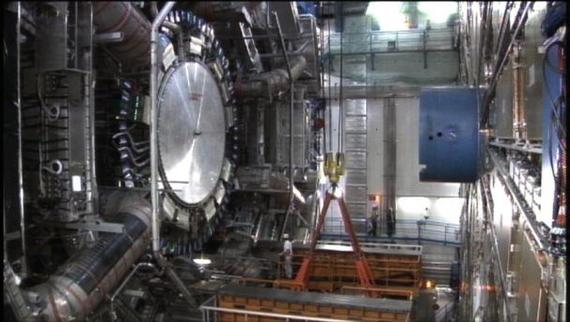

For the past five years, Antonio Pellegrino has been working on a high-pressure job: the scientist is leading an upgrade to the largest and most powerful particle accelerator ever built, which sits one hundred meters beneath the Franco-Swiss border at the European Organization for Nuclear Research (CERN). Commonly called the large hadron collider (LHC), the accelerator is a 27-kilometer-long ring in which particles such as protons and electrons are projected against one another at high speeds, recreating the conditions that existed one hundredth of a billionth of a second after the Big Bang – all for modern-day scientists to observe thanks to various high-precision detectors that sit inside the accelerator.

.

LHC was put on hold in 2015 for engineers and physicians to find ways to improve the accuracy of the accelerator’s detectors. The end-goal? Nothing short of understanding matter and getting better insights into the origins of the universe. To do exactly that, Pellegrino turned to a technology that is currently used to design products ranging from food and fashion to human cells : 3D printing. Thanks to a partnership with technology company 3D Systems, some parts of the LHC have been springing out of 3D printers, as part […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments