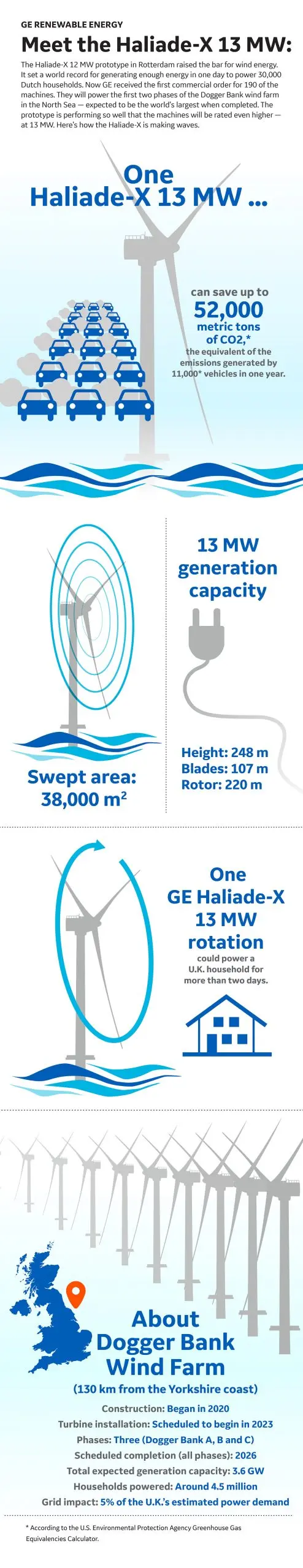

With blade diameter measuring more than two football fields, GE Renewables’ Haliade-X turbines are already the largest and most powerful in the world, capable of generating as much as 14 MW of energy. The ability to 3D print the turbine’s concrete base on-site, for direct transportation into the final at-sea location, will enable even larger systems to be built and deployed.

.

This approach is expected to enable the production of much taller wind turbines because turbine producers will not be hindered by transport limitations—today, the width of the base cannot exceed 4.5 meters for transportation reasons, which limits the height of the turbine. By increasing the height, the generation of power per turbine can also be increased substantially: for instance, a 5 MW turbine measuring 80 meters generates about 15.1 GWh a year. The same turbine measuring 160 meters would generate 20.2 GWh per year, an increase of 33%. How that scale is expected to become even greater, with new turbines reaching heights of 260 meters and even more. The first prototype of the Heliade X turbine became operational in Rotterdam Port, in the Netherlands, just over a year ago. It became the first wind turbine to produce 288 […]

Click here to view original web page at www.3dprintingmedia.network

0 Comments