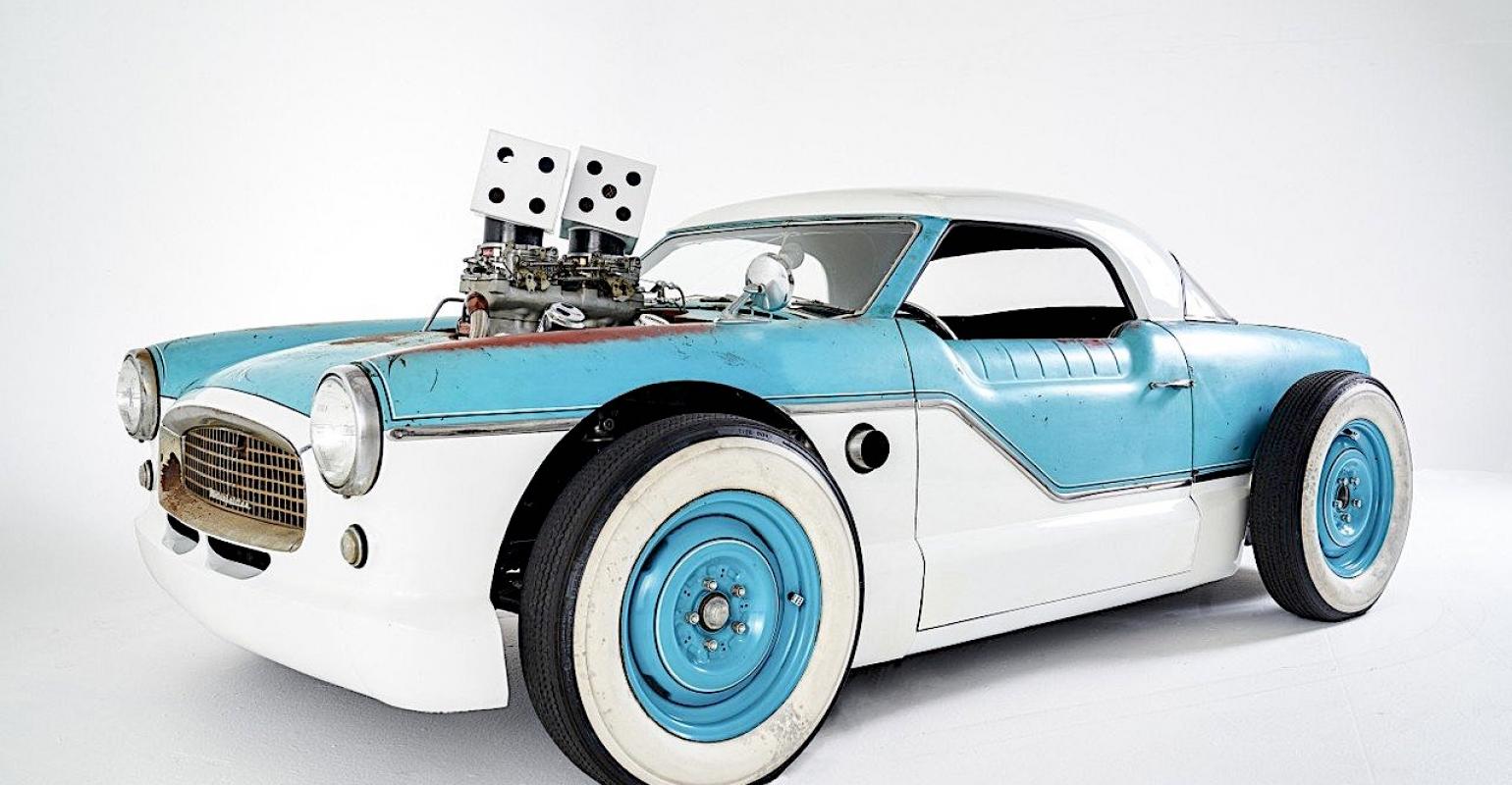

3D Systems Touch X haptic feedback device and Stratasys 3D printers aid Hot Wheels sculptors in translating exciting cars into 1:64-scale models. We are accustomed to engineers and designers developing production cars and trucks from prototype models, but the team at Mattel’s Hot Wheels brand has the challenge of going the other direction: from full-size to pint-size. While Hot Wheels has always built tiny 1:64-scale die-cast replicas of production models and has also developed its own unique custom designs, starting for the brand’s 50th anniversary in 2018, Hot Wheels has picked a fan’s real-life custom car for immortalization as a Hot Wheels toy car. This presents the new challenge of developing a model from a custom one-off vehicle, giving designers like Manson Cheung a fresh challenge compared to their regular work. The winner the first year was Luis Rodriguez’s and his “2JetZ” open-wheel jet car, while last year’s honoree […]

Creality Sermoon D1 review: An industrial-level 3D printer for under $700

Welcome to ZDNet's DIY-IT project lab, where I'm testing 3D printers for your entertainment and edification. Today,...

0 Comments