Heralded as a key technology to improve the environmental credentials and sustainability of manufacturing, 3D printing (or additive manufacturing) certainly meets the main criteria for sustainability – reduce, reuse and recycle.

.

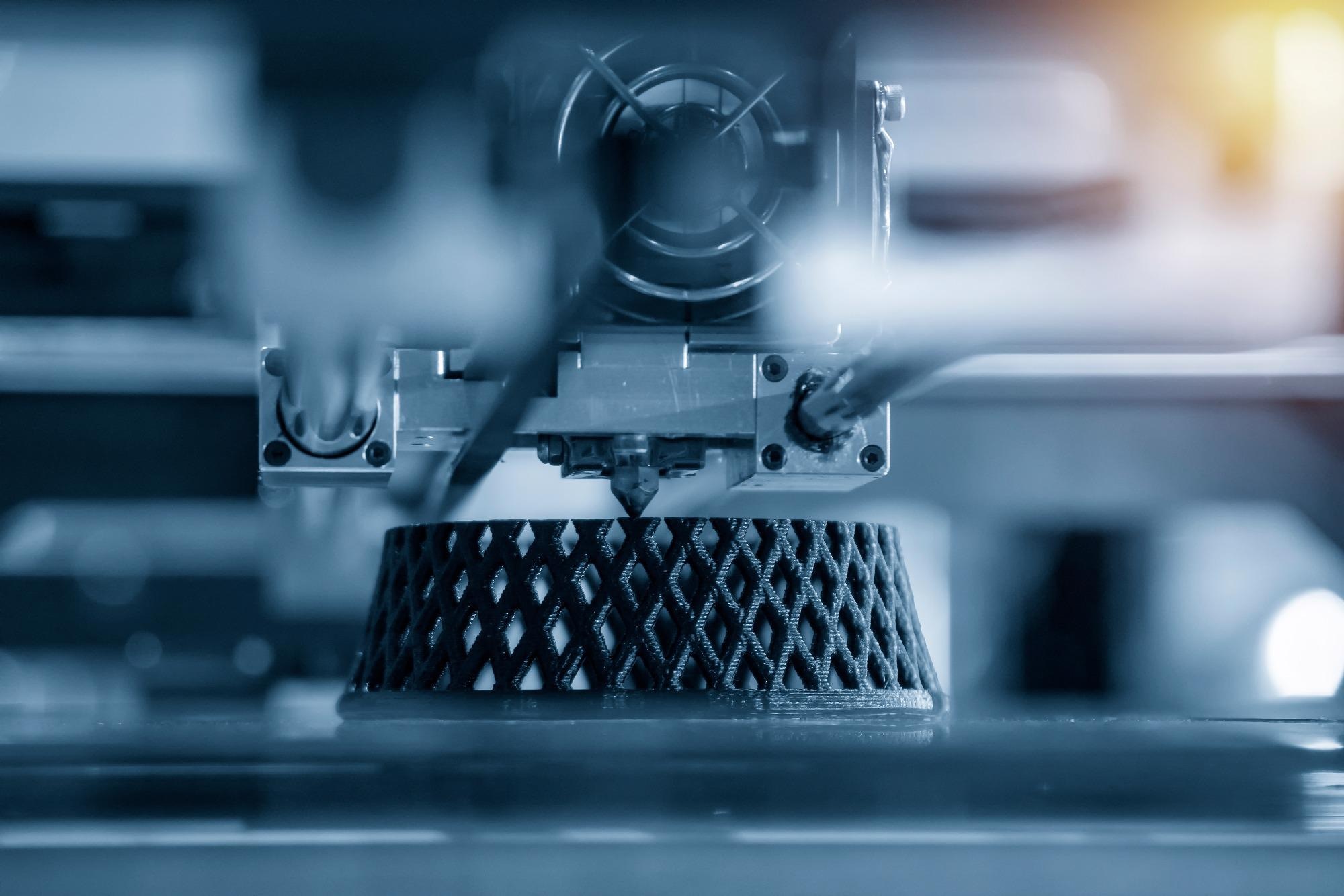

But upon closer inspection, how viable is it as an alternative to current manufacturing processes? Why 3D Printing? Using computer aided design, 3D printing builds an item up layer by layer in a very precise fashion. Initially plastics and metal powders were used as the feedstock for the process, but now resins, carbon fibers and even graphite and graphene are widely used too. The technique has many advantages over traditional manufacturing methods: it enables rapid prototyping, increases efficiency and permits the manufacture of unique items. It can also reduce production costs and carbon dioxide emissions from the process, and lower the energy consumption over the lifecycle of a product. For example, a Michigan Technological University study found 41-64% less energy was used to 3D print an item than manufacture it overseas and ship to the US; the result of fewer materials required and a reduced need for shipping. This article explores 3D printing in the context of the 3Rs – reduce, reuse and recycle to determine just how […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments