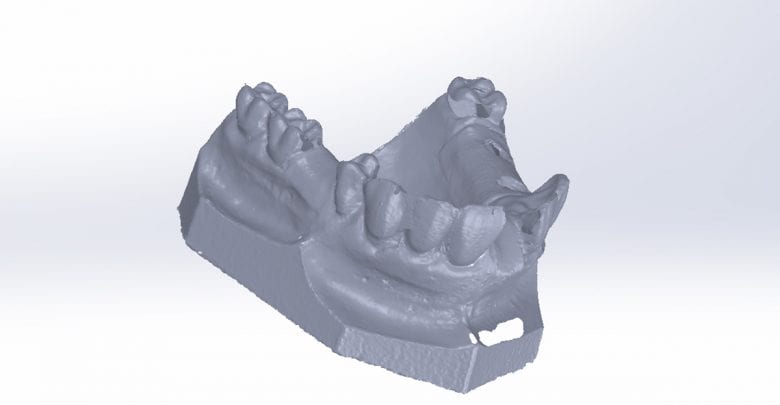

For some companies working with AM, specificity is key. That means focusing on a niche area of the market in order to face minimal competition. For others, including Croatia’s Medical 3D Design, a more holistic approach can pay dividends. Based just outside of Zagreb, Medical 3D Design is a 3D modeling company with many strings to its bow, offering both 3D modeling services and PolyJet 3D printing services, and targeting both the medical and dental industries. Sometimes less isn’t more.

.

According to Josip Rauker, Director of Medical 3D Design, additive manufacturing has allowed the company to do certain things — creating dental surgical guides, for example — that would have been impossible with traditional manufacturing methods. “The main advantage [of AM] is the easy production of nonstandard parts,” he says. “Production of parts that have complex geometries is much easier compared with other production methods.”

Click here to view original web page at www.3dprintingmedia.network

0 Comments