Now that desktop 3D printing has become widespread, there’s another production method crossing over into the DIY realm: Desktop injection molding.

.

It’s now possible “to create molds in-house to produce small, functional parts in production plastics,” writes Formlabs. “For low-volume production (approximately 10-100 parts), 3D-printed molds save time and money. They also enable a more agile manufacturing approach, allowing engineers and designers to easily modify molds and continue to iterate on their designs with low lead times and cost.”

.

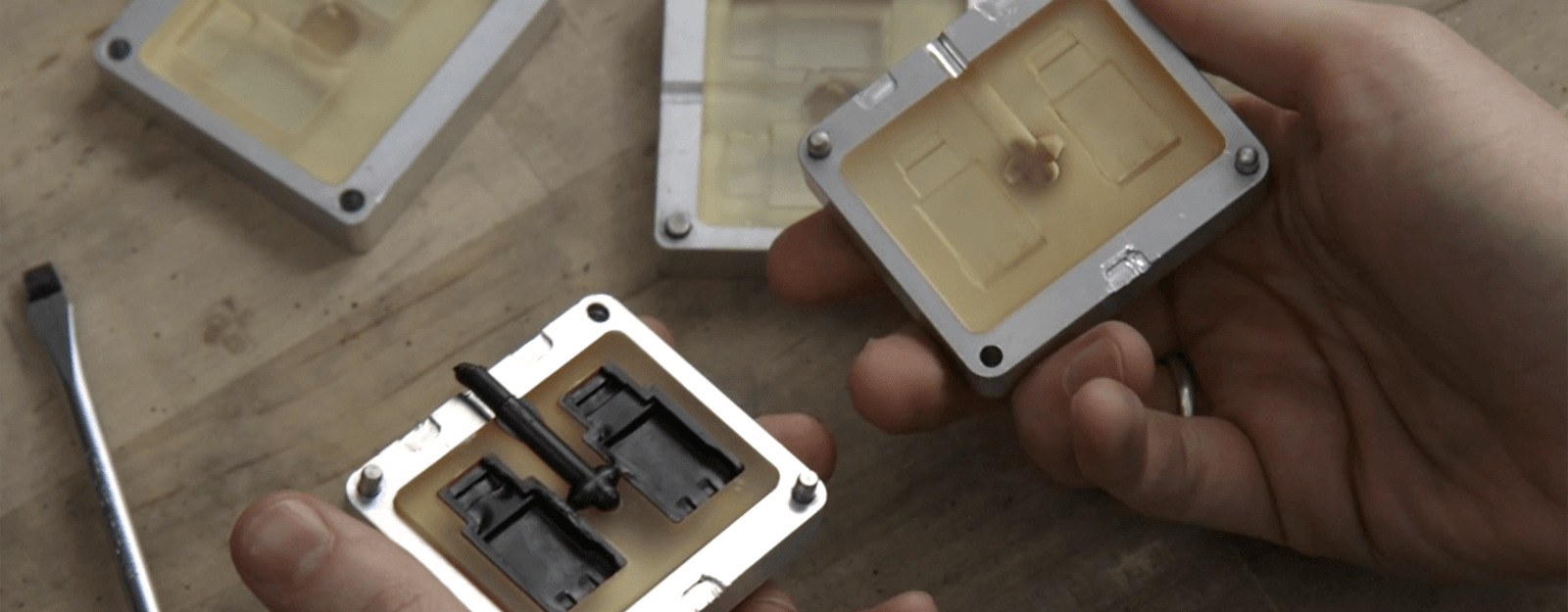

With a stereolithography (SLA) 3D printer, you can produce molds that are smooth and strong enough–at least with a little help–to use for injection-molding small runs (10 to 100 parts, Formlabs reckons). What they’ve done in their testing is placed the molds–which have cavities, gates and sprues, they’re the real deal–into aluminum frames, which prevent the mold from warping. You can work with standardized aluminum frames from injection molder manufacturers, […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments