3D printing with metal has become more than a trend. Now a mainstay as the industrial revolution via additive manufacturing continues, business owners are enjoying a host of benefits from metal 3D printing—from the ability to produce stronger, lighter parts faster to greater affordability in the end.

.

“Companies that feel like metal 3D printing is too far in the future…if additive manufacturing adds value to them whatsoever, and they’re not already investing in it, they’re already behind.” – Jason Harjo

.

.

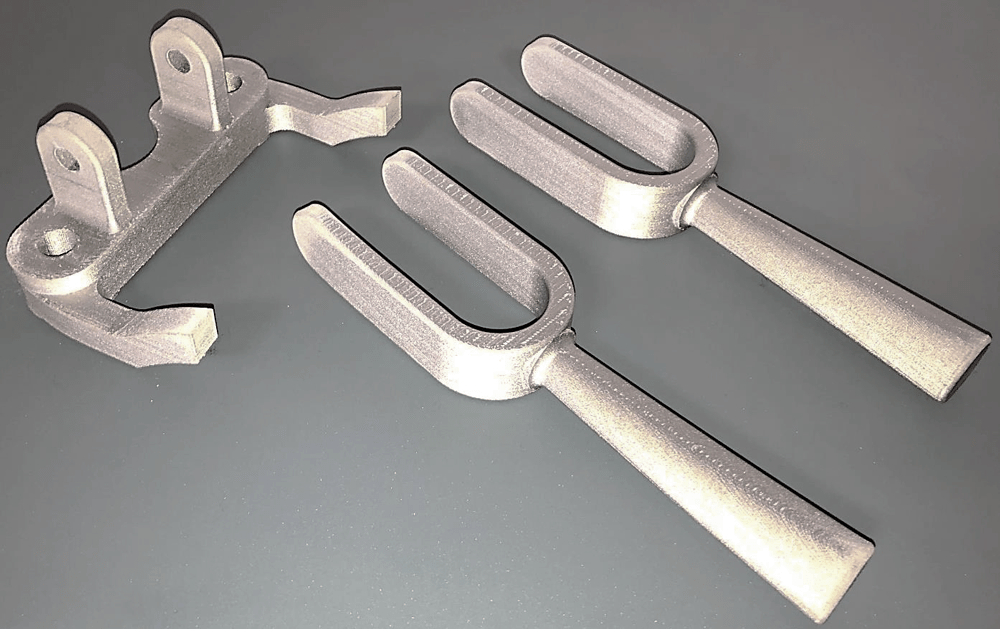

Now, Koch Industries -owned John Zink Hamworthy Combustion has purchased metal 3D printing technology from Desktop Metal , allowing them to fabricate and optimize parts on-demand as they continue in critical work building emissions control and clean-air combustion systems for facilities around the globe..

John Zink, based in Oklahoma, has been using the Desktop Metal Studio System for a few months now for rapid prototyping and production of small-volume […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments