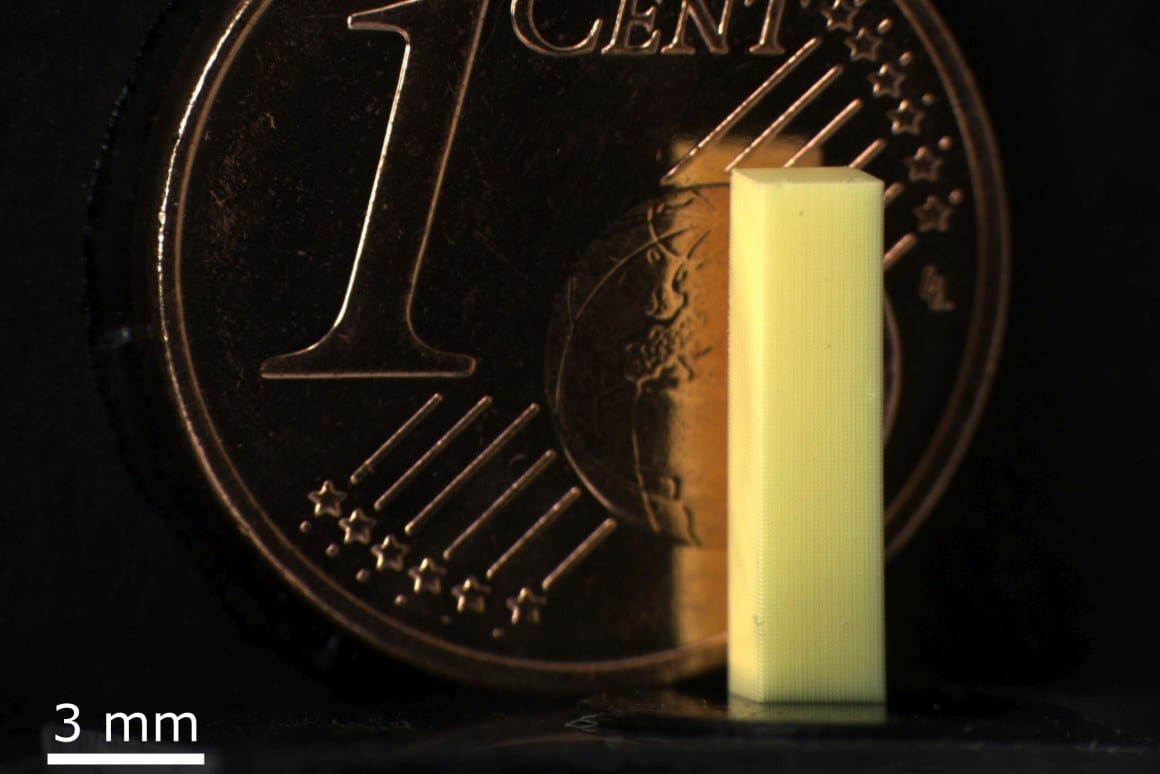

While large 3D-printed objects such as cars or buildings may get a lot of attention, the technology is also used to produce tiny, multi-faceted objects.

.

The latter could soon be whipped up faster and in more detail than ever before, thanks to a new printing system.

.

If you’re 3D-printing an object that’s just a few millimeters long – and which includes features that are a fraction of a millimeter in size – then the usual approach of extruding molten plastic out of a nozzle just won’t work. Instead, a laser is sometimes used to selectively harden a light-sensitive liquid polymer known as a photoresist. The laser beam focuses on specific areas of that material, one after the other, building up a three-dimensional structure in the process.

.

According to scientists at Germany’s Karlsruhe Institute of Technology, this process usually allows for a maximum printing speed of several hundred thousand voxels per second – a voxel is a single data point within a 3D grid, and is the equivalent of a pixel in a two-dimensional image. And although that may sound pretty fast, it’s actually only about one one-hundredth the speed at which inkjet printers produce 2D graphics.

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments