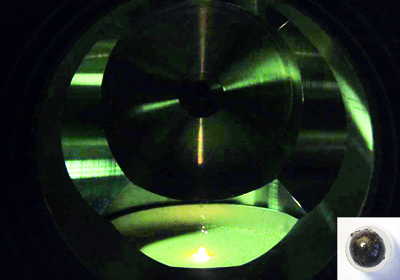

Research project in which moondust is laser-melted under lunar conditions suggests moon-based manufacturing is feasible. The spheres appear inconspicuous but they are unique. They consist of moon dust, molten under moon gravity in the course of the MOONRISE project.

.

Research institute Laser Zentrum Hannover (LZH) together with the Institute of Space Systems (IRAS) of the Technical University of Braunschweig carried out this unique experiment in the Einstein-Elevator at the Hannover Institute of Technology at the Leibniz University Hannover.

.

“With these spheres, we have come a big step closer to 3D-printing on the moon,” commented Niklas Gerdes, a scientist at LZH. A laser system developed by the LZH was used to melt synthetically produced lunar dust, the so-called regolith, under both lunar and microgravity conditions simulating the process as it might happen on the moon. Material samples adapted to possible landing site IRAS scientists have […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments