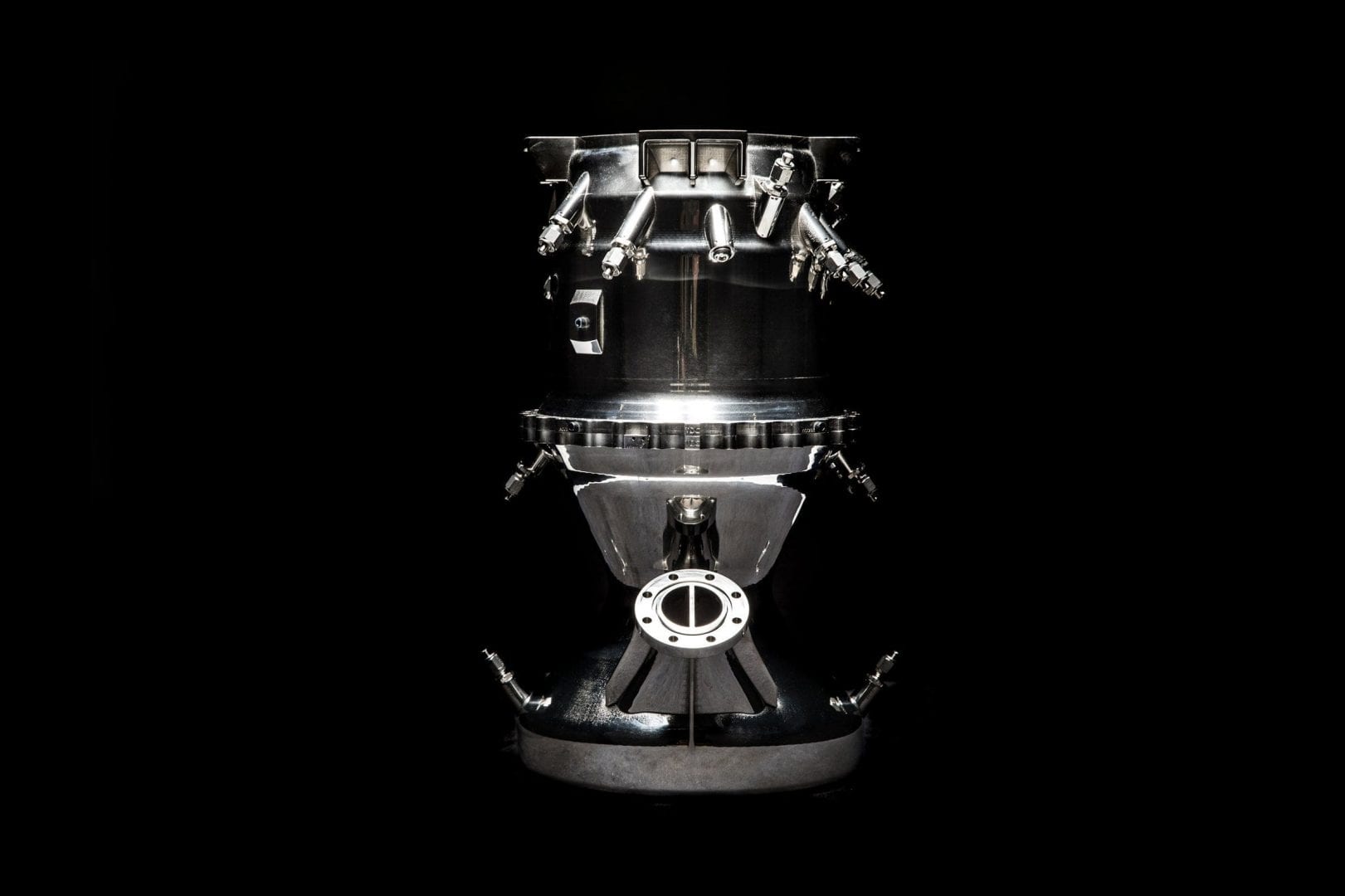

To make a 3D-printable rocket, Relativity Space simplified the design of many components, including the engine.

.

For a factory where robots toil around the clock to build a rocket with almost no human labor, the sound of grunts echoing across the parking lot make for a jarring contrast. “That’s Keanu Reeves’s stunt gym,” says Tim Ellis, the chief executive and cofounder of Relativity Space, a startup that wants to combine 3D printing and artificial intelligence to do for the rocket what Henry Ford did for the automobile. As we walk among the robots occupying Relativity’s factory, he points out the just-completed upper stage of the company’s rocket, which will soon be shipped to Mississippi for its first tests. Across the way, he says, gesturing to the outside world, is a recording studio run by Snoop Dogg.

.

Neither of those A-listers have paid a visit to Relativity’s rocket factory, but […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments