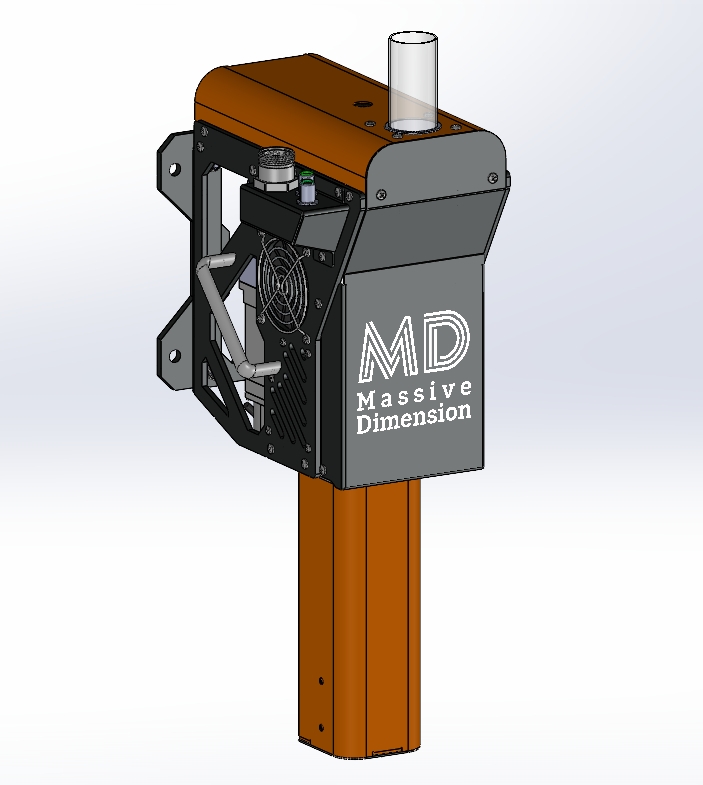

The MDPE10 is the newest direct-print particle extruder from Massive Dimension. The extruder head (since we are halfway through Q4, this seems unnecessary) reportedly outputs material at the rate of 10 lbs./hr.—five times faster than the company’s MDPH2 head.

.

The MDPE10 has three heating zones, two more than the company’s earlier-generation head, and a removable extruder screw with a 24:1 length-to-diameter ratio. The extra heat zones and longer screw help ensure the polymer build materials are melted, pressurized, and output more consistently during large-format 3D printing, says the manufacturer. Intended for printing large parts , the 40-lb. head works in conjunction with a CNC or robotic arm; extrudes a variety of materials, including ABS, PLA, HIPS, and PETG; and comes with four nozzles.

Click here to view original web page at www.thefabricator.com

0 Comments