Once thought destined mainly for prototyping, additive manufacturing is now increasingly employed in the development of spare parts, small series production and tooling in forward-thinking manufacturing industries such as aerospace, electronics, automotive and medical devices.

.

Among industries at the forefront of innovative manufacturing, the medical sector has emerged as a major segment driving the growth of additive manufacturing: France’s 3D MedLab operates at the forefront of this segment.

.

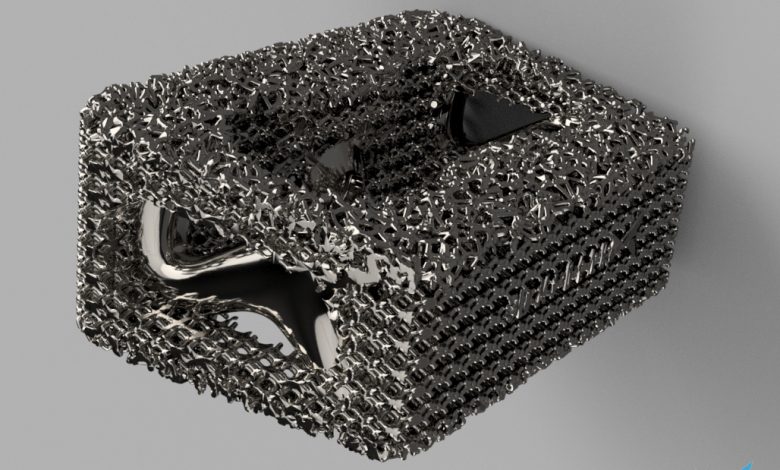

By fusing together metal powders layer by layer, using a number of different laser-based techniques, additive manufacturing can build complex components that would typically be very challenging – if not impossible – with more traditional subtractive manufacturing methods. The advantages of additive manufacturing include greater design freedom and customization, improved product strength and functionality, reduced assembly time for complex components, localized production, rapid time to market, mitigation of wastage, reduced obsolescence, decreased reliance on traditional suppliers, and even the creation of new materials with unique mechanical and behavioral properties.

.

Linde’s ADDvance O2 precision technology gives 3D Medlab precise granular control over oxygen concentration and humidity levels in the print chamber. The additive manufacturing technology landscape for the production of medical devices is a diverse one, with various […]

Click here to view original web page at www.3dprintingmedia.network

0 Comments