We’ve all built sandcastles at the beach: the mighty ramparts, the majestic turrets, the shark-filled moat. And if you’re like me, you were amazed at how well a bit of water made things stick together—at least until your big brother came along and kicked it apart in a fit of destructive glee.

.

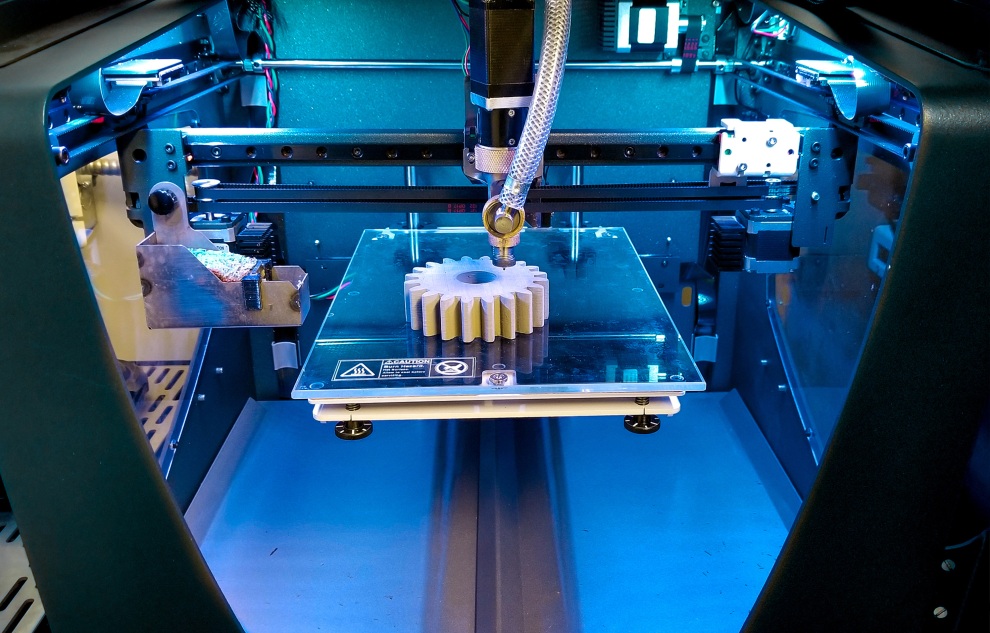

Entrepreneur Dan Gelbart also uses water to bind materials together, although his constructions are far more durable than weekend wonders from the beach.

.

The president and founder of metal 3D printing system provider Rapidia Tech Inc., Vancouver, British Columbia, and Libertyville, Ill., Gelbart has developed an approach to building parts that eliminates a time-consuming step inherent with competing technologies while greatly simplifying support removal. It also makes the joining of multiple parts no more difficult than dabbing them with a little water and holding them together—even […]

Click here to view original web page at www.thefabricator.com

0 Comments