Renishaw is collaborating with UK start-up Additive Automations, as part of a project to automate metal additive manufacturing (AM) post-processing.

.

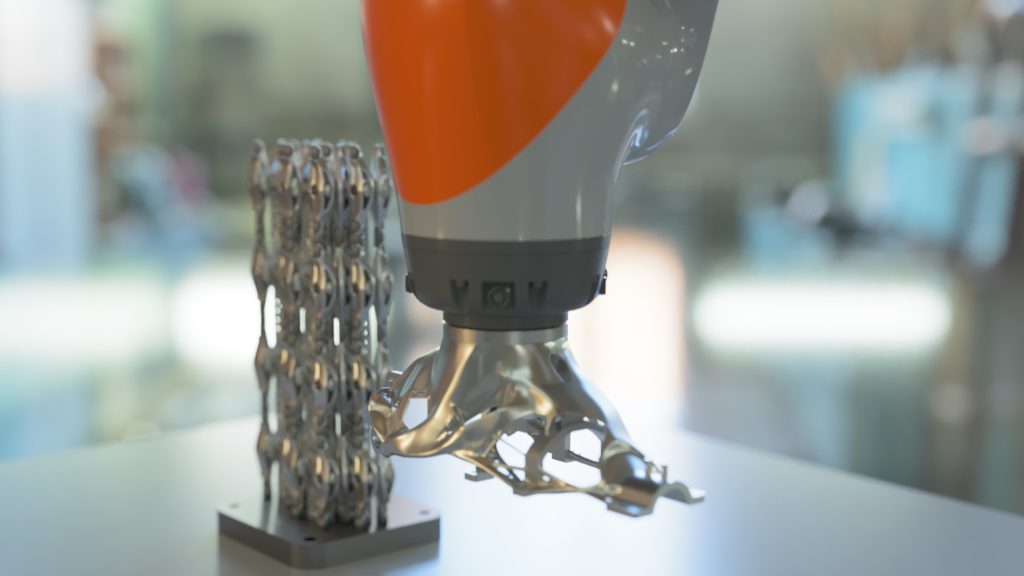

The project, which uses collaborative robots (cobots) to perform support structure removal, could reduce the average cost per part by 25%, improving AM’s potential as a cost-effective option for large volume production lines.

.

Sheffield-based Additive Automations creates robotic systems to automate additive manufacturing. After obtaining funding from UK and Canadian bodies, its founder and CEO, Robert Bush, collaborated with both Renishaw and the University of Sheffield Advanced Manufacturing Research Centre (AMRC). Since August 2019, Renishaw has been assisting Additive Automations’ progress by providing its industry leading AM expertise. Renishaw provided four examples of AM builds so the start-up could demonstrate its support structure removal system. The four AM parts were designed for medical, oil and gas, automotive and mechanical engineering applications. Testing its robotic system on parts already being […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments