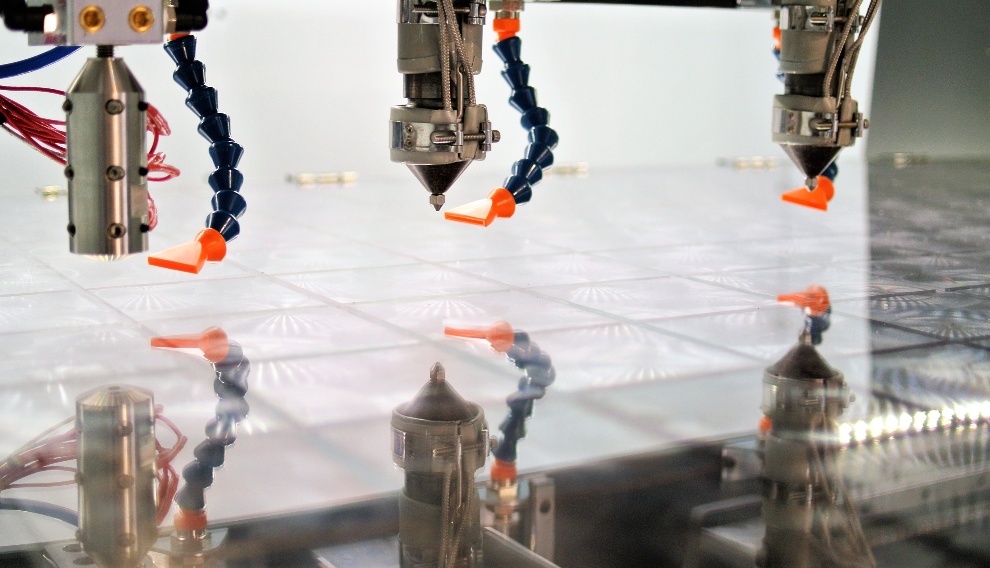

Titan Robotics Ltd. builds 3D printers that extrude polymer pellets, a technology aimed at reducing material costs, increasing material options, and speeding the printing process.

.

“We set out to solve the challenges that had kept 3D printing a prototyping business,” said Clay Guillory, the founder and head of services at Titan, Colorado Springs, Colo. “We saw pellet extrusion as the avenue to get there.”

.

Pellet-based extrusion technology is similar to fused filament fabrication (FFF). One difference is that pellets are an injection molding-type feedstock, unlike the filament used with traditional FFF printers. Titan CEO Rahul Kasat said pellets, which are used to make filament, are one-tenth the cost of filament. “So you skip that extra conversion step and [don’t pay] the additional cost of making filament.”

.

In addition, Kasat pointed out that a pellet extruder melts and deposits plastic significantly faster than filament-based machines. This translates into faster print speeds for both large parts and large numbers of parts. How much faster? According to Guillory, printing a large part with filament can take weeks, while a pellet extruder can do the job in […]

Click here to view original web page at www.thefabricator.com

0 Comments