Back when you were in high school, shop class was filled with woodworking tools, lathes, drill presses, and maybe the occasional welder. Nowadays, a well-funded school will teach kids how to use alien technology and act like it’s nothing.

.

From CNC routers to laser cutters and 3D printers, the once basic engineering technology is now moving toward the future before our very eyes.

.

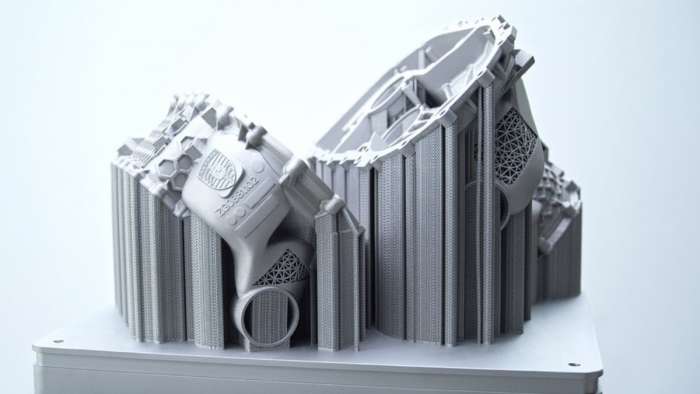

Porsche is a company that embraces 3D-printing as a manufacturing tool for real metal parts. Were not sure if this has been done before in the auto industry but we think it’s worth looking into. The parts involved in this new process are mainly the outer housings for electric-drive components and hardware. Using this technique, Porsche has made everything lighter, stronger, and more durable. Image: Porsche Media Electric Drive Housing The rear-end of an electric car is very similar to that of a gas-powered car believe it or not. An electric drive unit looks like a big beefier version of the Ford 9-inch you have in your old Camaro . Even though the Taycan , Porsche’s only all-electric car, is more technologically advanced than other EVs , there is always room […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments