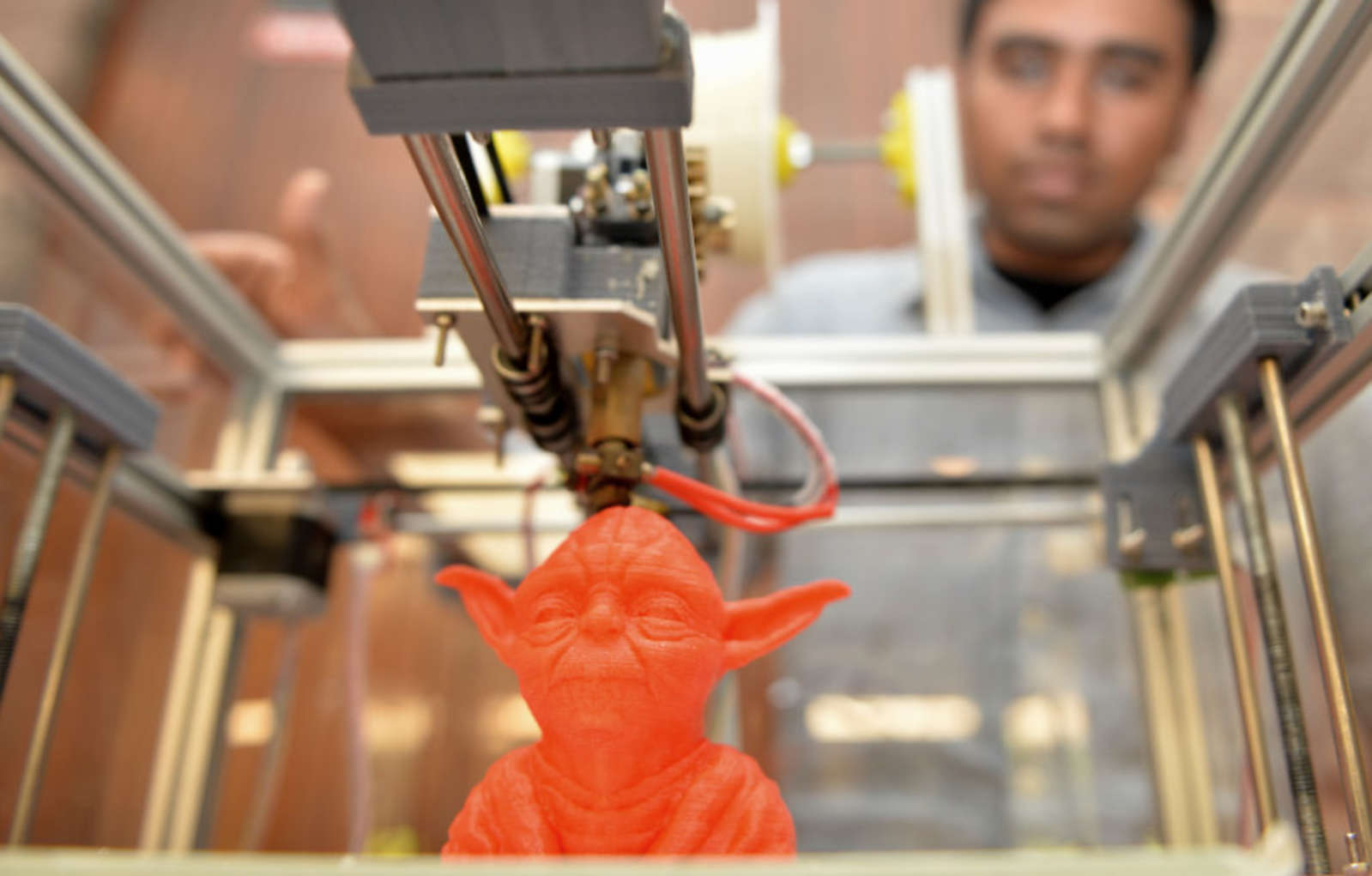

Use 5-axis, they did not. Two researchers at Penn State have created a new system for five-axis additive 3D-printing that reduces the amount and density of support materials needed for making printed objects.

.

In a paper entitled “ Process planning for five-axis support free additive manufacturing ,” doctoral candidates Xinyi Xiaoa and Sanjay Joshi proposed using a 3D printer with a movable build plate or extrusion arm to turn objects in 3D space as they’re printed, thereby making every surface “flat” as its being extruded. Normal additive 3D printing starts with the bottom of an object and adds layers as it prints. When objects are bigger on the top than the base or overhang over the main base—imagine tree branches overhanging a trunk—traditional printers add support material that is removed and thrown away.

.

“Removal of the support structures is costly and time-consuming, especially for metal parts,” wrote the researchers. The printer prints as much as it can at a certain axis and then turns slightly to reduce overhang and supports. Screenshot: Penn State University In other words, this is 3D printing squared, with another axis added to the printer in order to maximize the process as the object grows. […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments