In ‘ Laser Sintering of Thermoset Polyimide Composites ,’ authors Kathy C. Chuang, Timothy J. Gornet, Kate Schneidu, and Hilmar Koerner explore additive manufacturing with blended materials, meant to refine the process further and offer better performance overall.

.

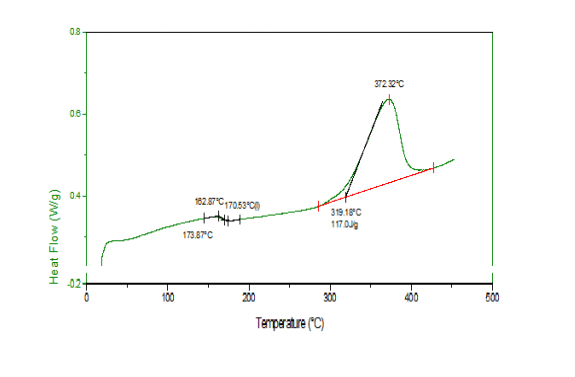

Polyamides such as nylon are commonly used in SLS 3D printing, but objects printed may be weaker in comparison to the use of other materials. The researchers attribute this to ‘lack of polymer inter-chain connection in the z-direction.’ They also explain that their true motivation behind development of an SLS process for thermoset resins is to have the capability of 3D printing at higher temperatures (to 250-300 °C) so composites can be used for aerospace.

.

Their previous study showed that resin viscosity was too low, with the reactive PEPA endcap remaining uncured: “As a result, the LS-printed resin chips could not hold much integrity upon postcure above 250 °C. To overcome […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments