Over the years, cycling component manufacturers have gone to great lengths to find ways to improve the bikes that we ride.

Frames have gotten lighter and stronger, chainsets have gotten smoother and more efficient, and brakes have transitioned from pads to discs, all in an effort to cut weight and improve safety, while also getting faster.

Over that time, the bike saddle has often been overlooked, forcing riders to settle for seats that are often uncomfortable and based on decades-old designs. Today, that all changes as Specialized has unveiled a completely new technique for designing and building bike seats that it claims will revolutionize the industry forever.

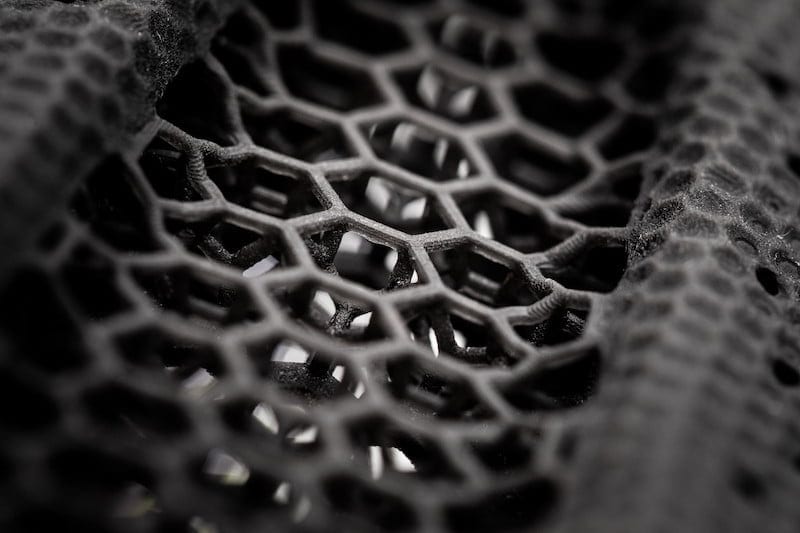

Using a process called Digital Light Synthesis (DLS), Specialized has developed what it calls Mirror Technology , a material that is far more tunable and versatile than traditional foam padding. So much so that the company says that Mirror can replace padding […]

Click here to view original web page at www.digitaltrends.com

0 Comments