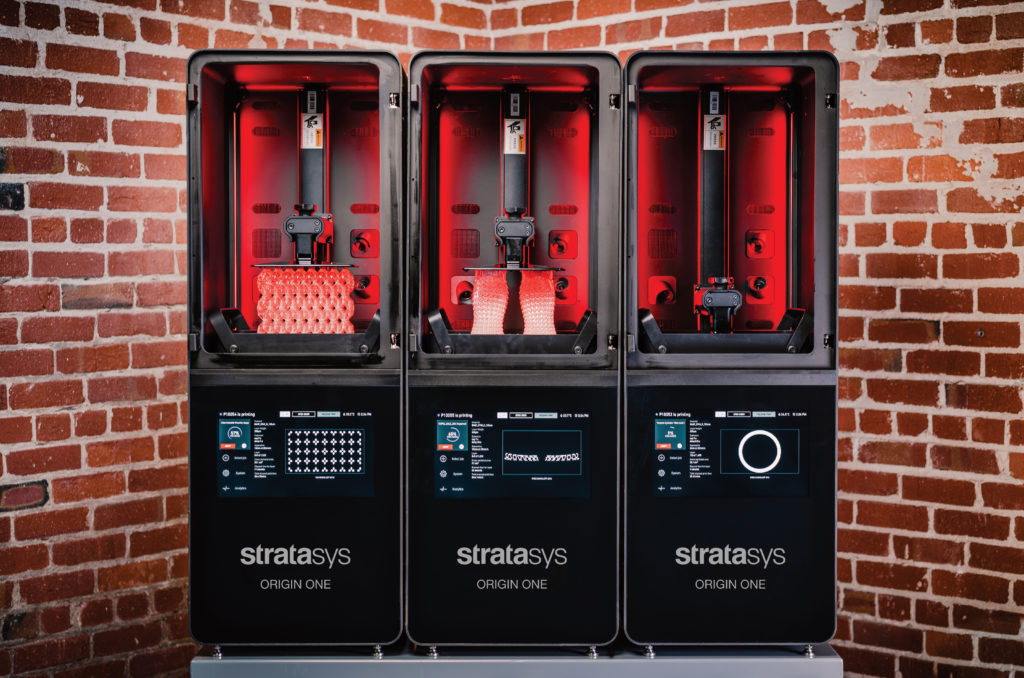

Stratasys has introduced three new 3D printers that together address a large portion of the multi-billion-dollar market opportunity in additive manufacturing of end-use parts.

.

The systems collectively are aimed at accelerating the shift from traditional to additive manufacturing for low-to-mid-volume production applications underserved by traditional manufacturing methods.

.

“We are accelerating into the Additive Manufacturing 2.0 era, in which we see global manufacturing leaders move beyond prototyping to fully embrace the agility that 3D printing brings to the entire manufacturing value chain,” said Stratasys CEO Yoav Zeif. “The disruptions we are seeing today on both the supply and demand side of global supply chains are a clear sign that the status quo isn’t working. Additive manufacturing gives companies the total flexibility to decide when, where, and how to produce parts. That’s why we’re committed to being the complete provider of polymer 3D printing solutions for our world-class customer base.”

.

Last year, Stratasys accrued more than 25% of its revenue from manufacturing-related applications. Going forward, with a comprehensive and integrated portfolio of 3D printing hardware, software, materials and services solutions, Stratasys estimates that its manufacturing revenue growth will outpace other segments, growing at an annual rate of over 20% starting in […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments