Addressing the growing demands of engineers and designers to deliver production-grade, custom 3D-printed tooling and parts, Stratasys unveiled several new durable, temperature and chemical resistant FDM thermoplastics.

.

Meeting the specific requirements of 3D printed applications in manufacturing, these materials can accommodate high temperatures and challenging requirements common on the production floor.

.

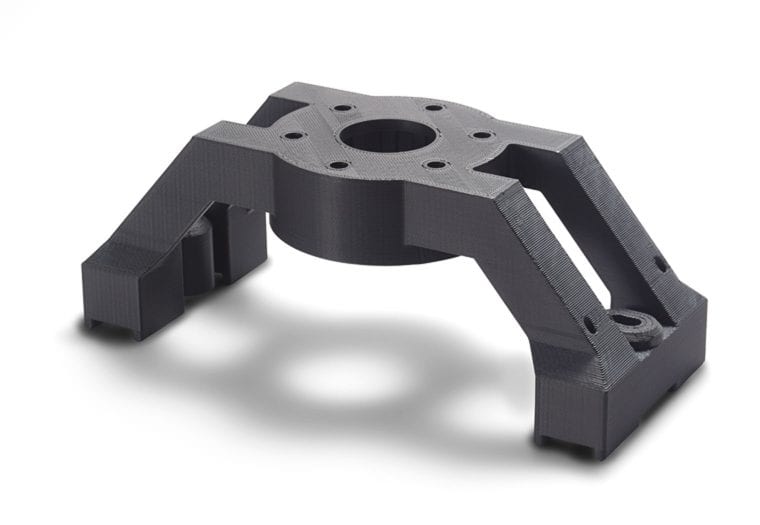

Materials introduced today include Antero 840CN03 for the Stratasys Fortus F900 3D printer, and Diran 410MF07 and ABS-ESD7 for the Stratasys F370 3D printer. Each of these thermoplastics are well-suited to handle the requirements of manufacturing applications in industries such as automotive and aerospace to engineer advanced 3D printed jigs and fixtures, tooling, prototypes and production parts.

.

Developed for the F900 3D printer, Antero 840CN03 is the second PEKK-based polymer now offered by Stratasys in its portfolio of proprietary Antero high performance polymers – and leveraging the Kepstan PEKK technology from Stratasys strategic supplier Arkema. The new Antero […]

A Perfect Pair: 3D Printed Drones

Drones bring great energy to the design and 3D printing realm, with engineers engaged in developing new technology...

0 Comments