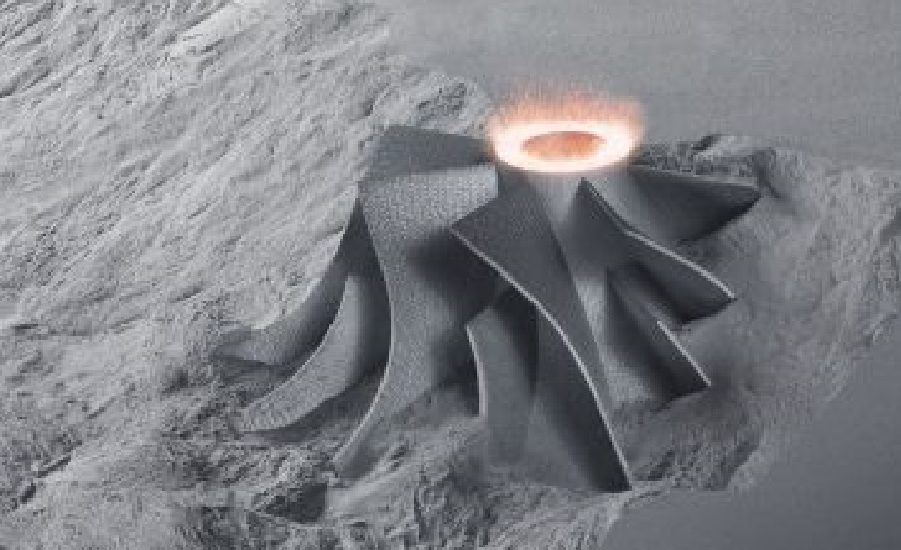

U.S. Army researchers have discovered a way to monitor the performance of 3D printed parts, which tend to have imperfections that affect performance in ways traditionally-machined parts do not.

.

In the paper, “In-Situ Fatigue Monitoring Investigation of Additively Manufactured Maraging Steel, Army researchers verifit that they can detect and monitor the wear and tear of 3D printed steel through sensor measurement. For the Army, these types of measurements help soldiers maintain readiness because these indicators help predict when parts will degrade or fail, and need replacement. “3D-printed parts display certain attributes, due to the manufacturing process itself, which, unchecked, may cause these parts to degrade in manners not observed in traditionally-machined parts,” says Dr. Jaret C. Riddick, director of the vehicle technology directorate at the U.S. Army’s Combat Capabilities Development Command’s Army Research Laboratory. “Because of this, it’s commonly understood that […]

A Perfect Pair: 3D Printed Drones

Drones bring great energy to the design and 3D printing realm, with engineers engaged in developing new technology...

0 Comments