Rhe latest version of Volume Graphics ’ (Charlotte, N.C., U.S.) high-end industrial computed tomography (CT) data analysis software suite, version 3.5, brings enhanced capabilities to manufacturers looking for better ways to inspect parts and improve designs.

.

According to the company, the non-destructive part evaluation software can interpret CT data from scans of almost any part and material. Version 3.5 provides more powerful automated design-geometry adjustment and repair tools that can be used to correct and/or offset issues that stem from the manufacturing process itself, Volume Graphics says.

.

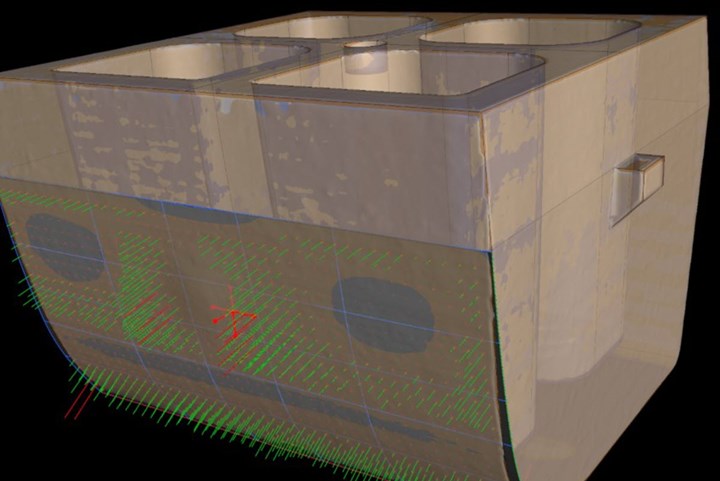

Moldmakers, casting shops and additive manufacturing (AM) providers alike are said to be able to employ the software to detect and visualize material and/or design defects or distortions, and then employ sophisticated capabilities to correct their CAD designs, compare values against nominal limits and ensure that final part quality meets applicable industry standards. The company highlights version 3.5’s completely reworked manufacturing geometry correction module (Fig. 1). This software module, says Volume Graphics, benefits all those who work with some kind of mold (i.e., injection molders or casters). Enhancements in usability, with continuous updating and feedback on quality, give the CAD designer […]

Click here to view original web page at www.compositesworld.com

0 Comments