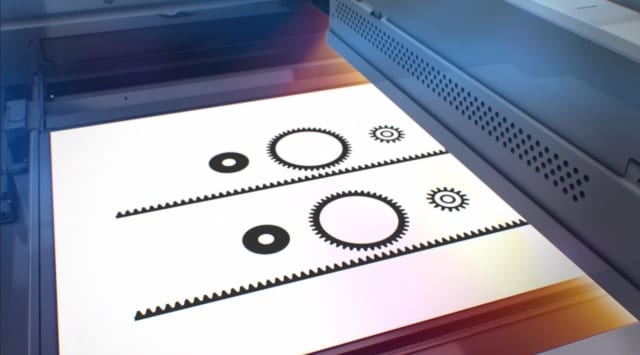

When HP debuted its Jet Fusion 3D Printing Solutions in 2016, it introduced an entirely new industrial additive manufacturing technology.

.

While powder melting, light catalyzed solidification and filament deposition systems have been refined steadily over the last 20 years, the key constraints of speed, cost and resolution remain issues that restrict the adoption of additive as a true production technology. With a large powder bed designed to hold nested batches of parts, HP Jet Fusion 3D printers, powered by Multi Jet Fusion (MJF) technology can deliver high productivity – making them a serious option for industrial-scale polymer 3D printing.

.

That’s why engineering.com took a closer look at the machines, comparing them not only to other additive techniques but also to traditional manufacturing methods. Outside of the 3D printing business, HP is a leader in microfluidics (the ability to manage fluids at a microscopic level). It’s this ability to place […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments