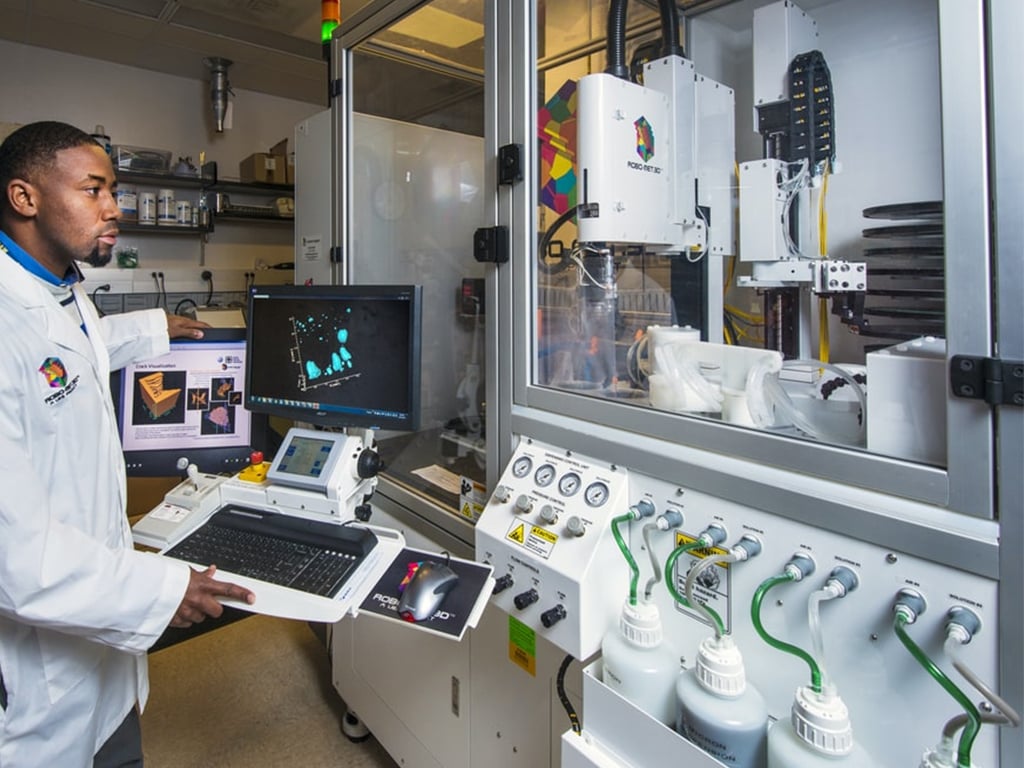

BR Research It is oft cited that the future of manufacturing lies in additive manufacturing – or more commonly known as 3D printing.

.

And many are now saying that COVID-19 could be a tipping point for technology adoption in manufacturing. During 2020, the global pandemic stifled manufacturing – disrupting conventional supply chains and workforce, forcing plants to shut down amid spiking demand for essentials as well as health/medical equipment. But a study by Markforged – a privately-held US additive manufacturing company – “COVID-19 Impact on Supply Chains: Global Additive Manufacturing Industry Report”, shows that modern manufacturers – those who adopt digital manufacturing solutions such as 3D printing – were the most resilient, reporting that they’ve been operating as usual while other manufacturers scaled back production. Over 60 percent of the respondents with industrial 3D printers reported time and cost savings, while nearly half respondents reported “business as usual” operations, and 2 percent reported starting producing new products. Many also reported pivoting to printing personal protective equipment (PPE). While global manufacturing might be getting ready for a new level of technology integration to boost economic progress, Pakistan unfortunately has a rather restrictive stance on the import of 3D printers. The […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments