Despite the fact that its most recent CEO, Vyomesh Joshi, has headed for retirement , 3D Systems is continuing in his vision for vertically integrated industrial 3D printing. The company has announced a new solution for batch production of 3D-printed orthodontic models.

.

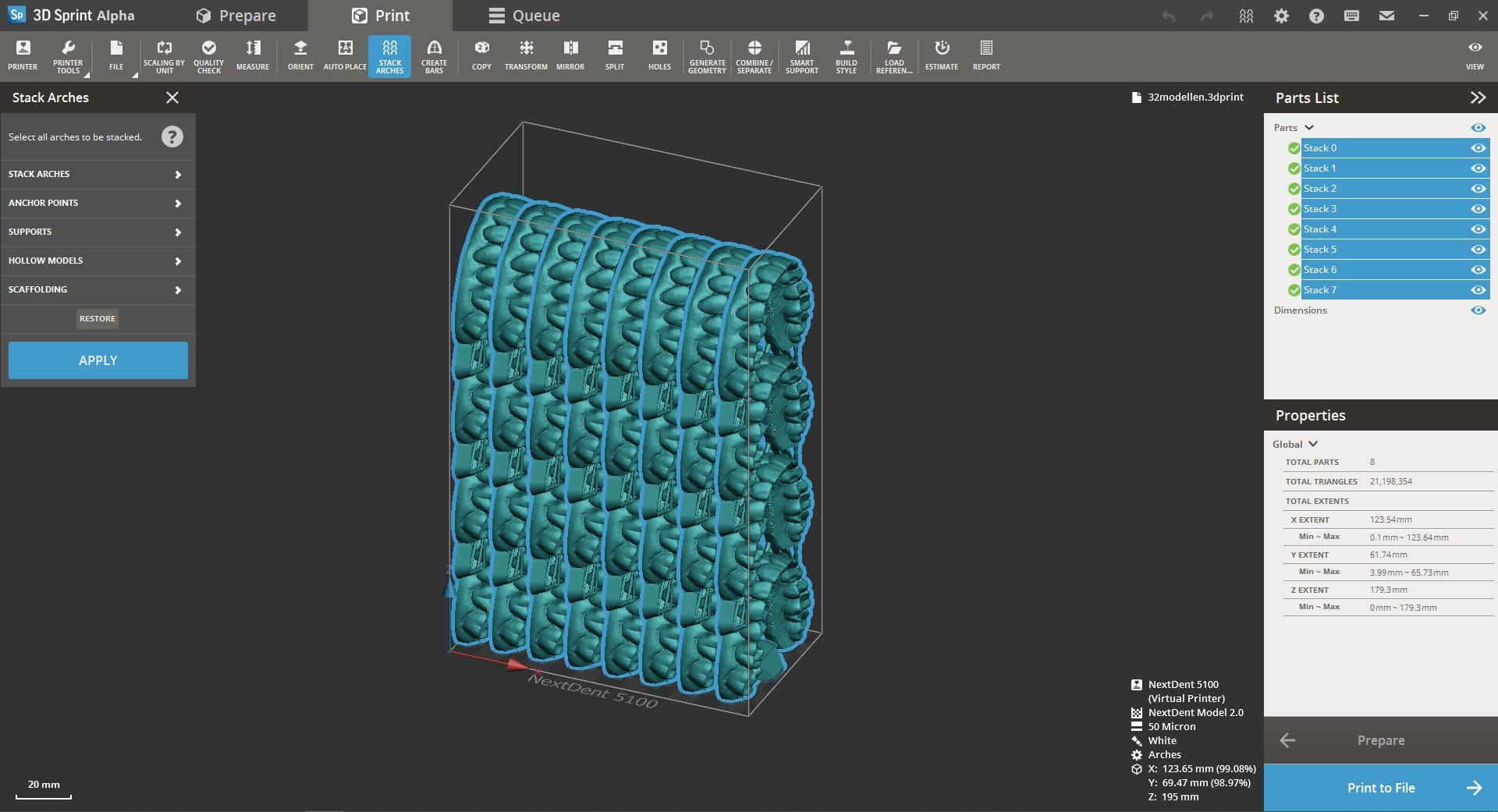

Ahead of LMT Lab Day 2020 , the company announced a software workflow for 3D printing up to 30 orthodontic models in a single print using its NexDent 5100 3D printer, NextDent Model 2.0 Software, and 3D Sprint software. Altogether, 3D Systems suggests that dental labs and clinics could potentially produce 120 models in just eight hours, depending on the size and geometry of the models.

.

The heart of the workflow is a new auto-stacking feature within 3D Systems’ 3D Sprint software, which makes it possible to automatically prepare and place dental models on the build plate with a single click. The tool includes smart nesting and […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments