California-headquartered digital manufacturing company VELO3D, which recently raised $28 million in a Series D funding round, just announced that it has developed a process for 3D printing parts out of foundry-grade Aluminum F357 on its Sapphire metal 3D printers.

.

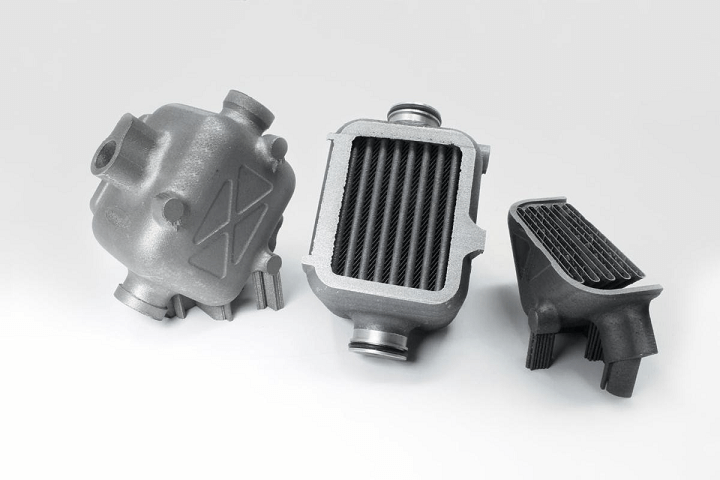

The commercial release of this capability is significant, because the material is traditionally manufactured with casting technology, but now it can be 3D printed in intricate, complex shapes that casting just can’t achieve. “Aluminum F357 has already been certified for mission-critical applications—unlike some exotic alloys—so it was a logical addition to our materials portfolio. We will continue to add more compatible materials that enable customers to print parts they couldn’t before, yet with even better material properties than traditional manufacturing,” explained VELO3D Founder and CEO Benny Buller. This aircraft-grade aluminum alloy, which is well-suited for laser powder bed fusion 3D printing, lets companies in the aerospace, defense, […]

A Perfect Pair: 3D Printed Drones

Drones bring great energy to the design and 3D printing realm, with engineers engaged in developing new technology...

0 Comments