FAW-Volkswagen Automobile Co., Ltd , a joint venture between FAW Group, Volkswagen and Audi, has revealed it is producing prototypes for more than 5,000 parts a year with Farsoon’s Laser Sintering technology.

.

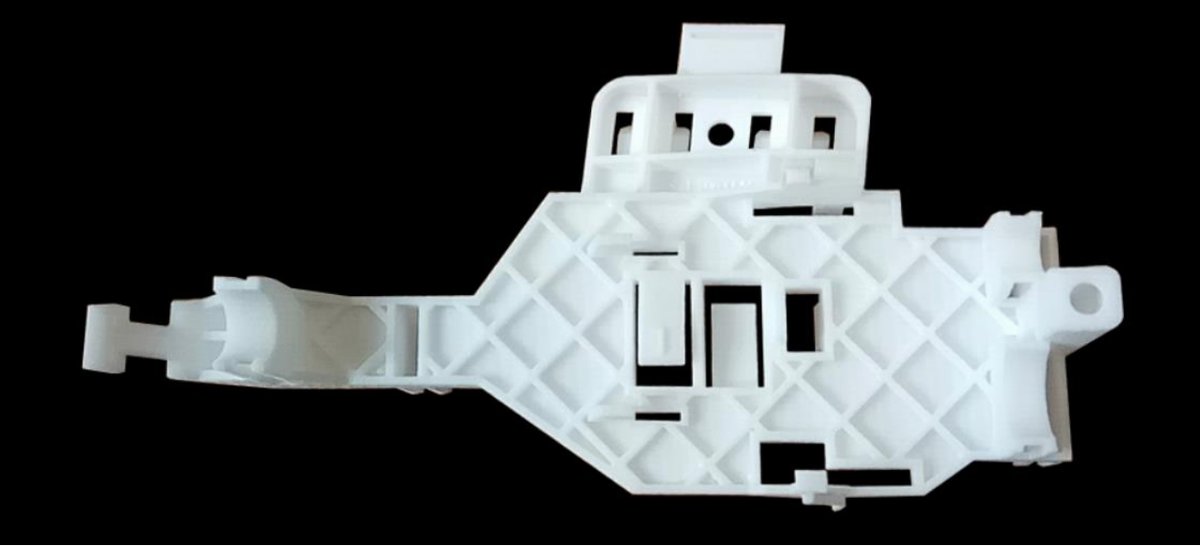

The company, founded in 1991 in Changchun, Jilin Province and today producing millions of cars every year, has long been a user of 3D printing for prototyping means, first adopting the Fused Deposition Modelling and Stereolithography processes, and later installing Farsoon’s HT403P machine. With Farsoon’s Laser Sintering technology, FAW-Volkswagen is building functional prototypes of components like bumper guide brackets and air ducts. When prototyping and manufacturing the air duct component, which controls air flow into the interior of the vehicle, the main challenge is the complex hollow structure. Typically, this part would be produced with blow moulding, but when only a small batch of prototypes is required, this is an expensive process – costs could be as […]

A Perfect Pair: 3D Printed Drones

Drones bring great energy to the design and 3D printing realm, with engineers engaged in developing new technology...

0 Comments