3D Systems FabPro 3D Printer

$2,495.00

The FabPro 3D Printer from 3D Systems, the inventors of the 3D Printing industry, raises the bar for industrial entry-level 3D printing enabling you to produce high-quality parts with lightning speed, remarkably low operating costs and unsurpassed ease of use.

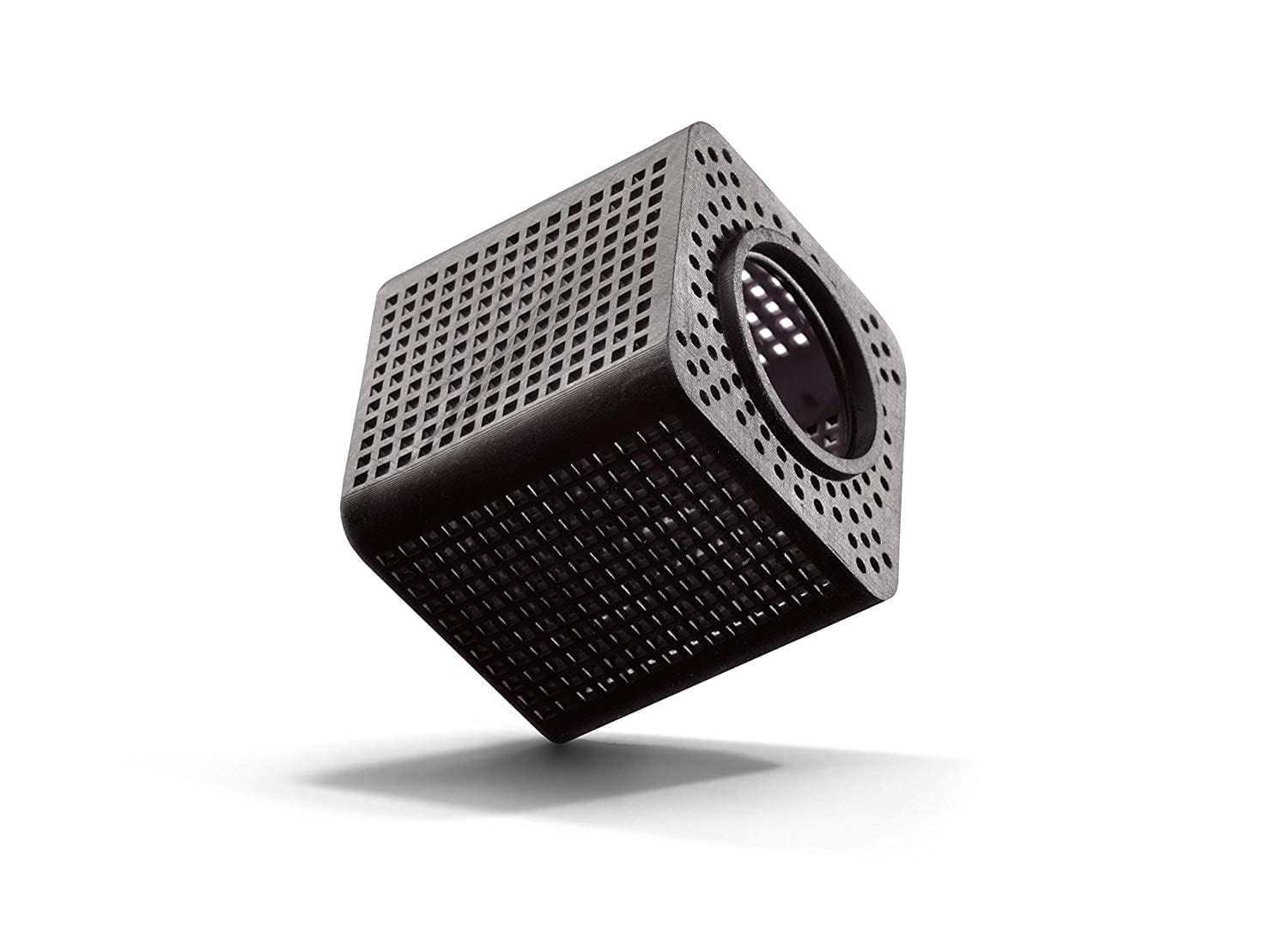

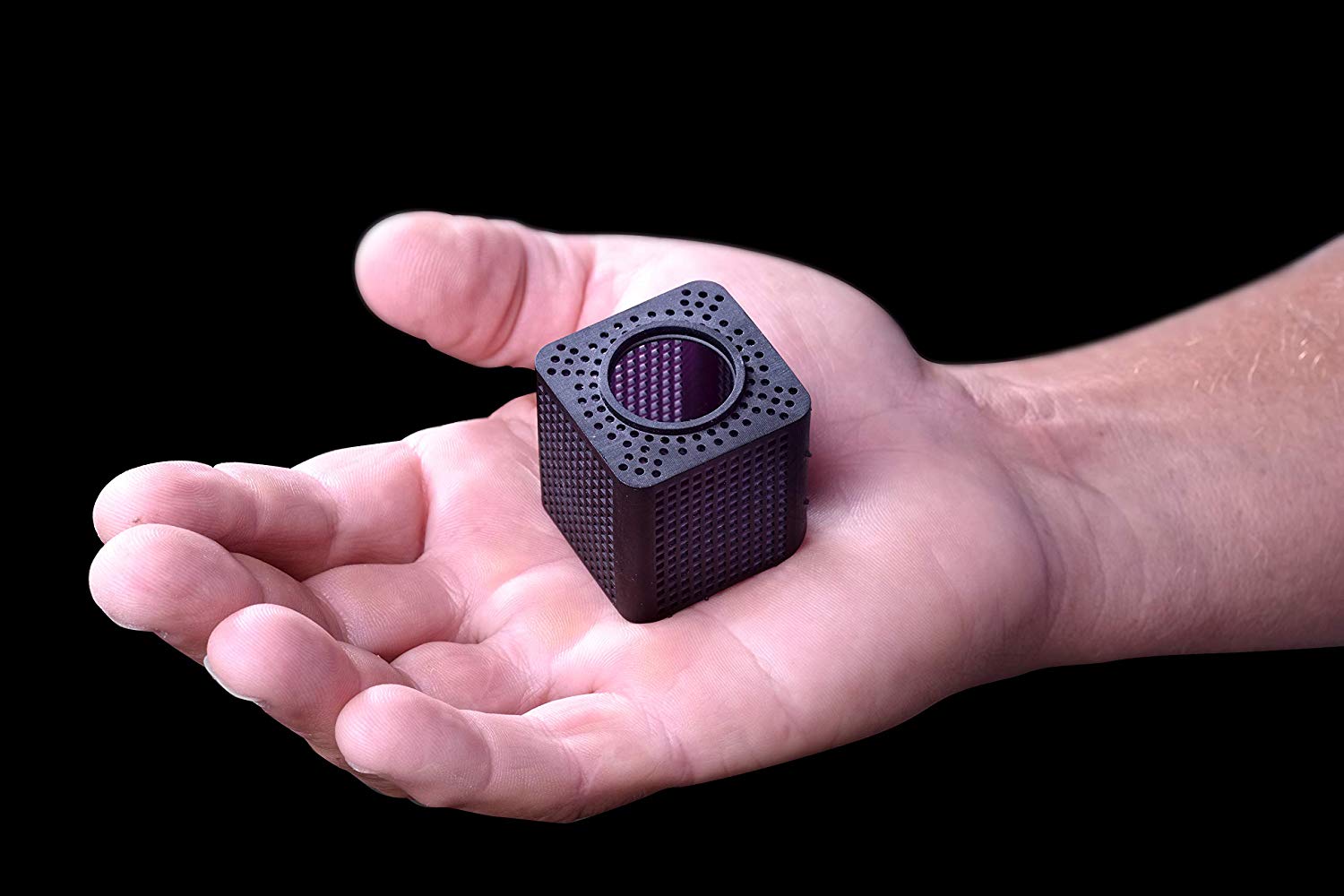

- Applications: Ideal for prototyping, engineering, and jewelry applications, the FabPro excels at low-volume, small-part prototyping and direct 3D production across a wide range of high-quality materials.

- Prototyping and Production: Print prototypes, functional assemblies and production parts with tough engineering plastics and elastomeric materials.

- Jewelry: Create and produce custom jewelry with small, fine-featured models and patterns for investment casting.

- Choose from a wide range of materials to use with your FabPro 1000 printer

- Produce models in hours, not days. The FabPro 1000 can create higher quality parts with precision and smooth finish at up to three-times-faster throughput print speeds than competing systems. How? Our technology uses a projector to image each layer for easy and precise printing, with the ability to build several smaller parts on a single platform for increased productivity.

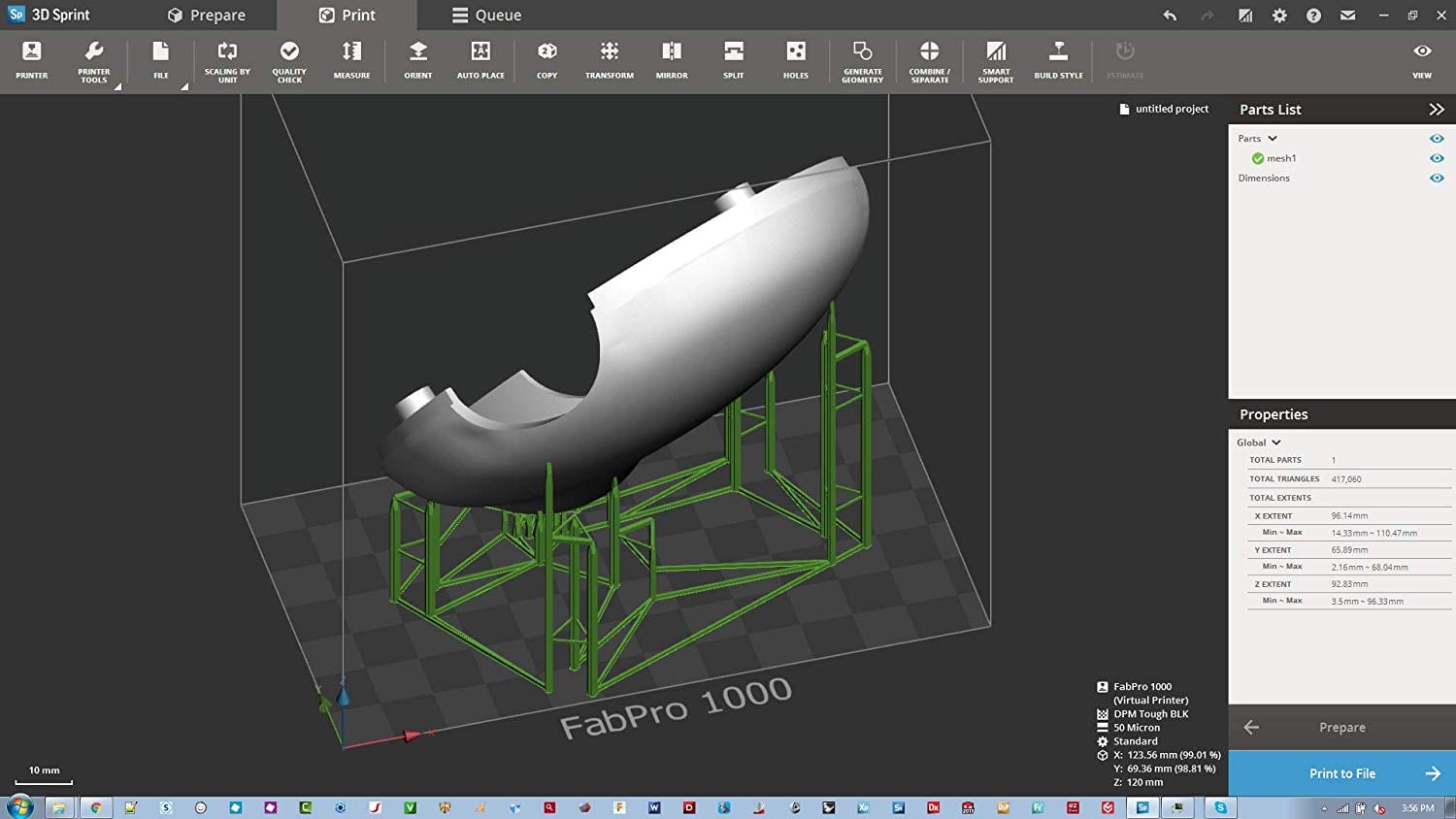

- Engineered for material efficiency and consistent, repeatable runtimes, making 3D prototyping and production more accessible and affordable than ever before. 3D Sprint file preparation and print management software helps manage material usage with less waste with optimized print builds and support structures. This combination of fast print speeds and optimized printing all leads to lower part costs and lower Total Cost of Operations. Preparing part files for printing and monitoring print jobs is easy with 3D Systems 3D Sprint software, which comes standard with every FabPro.

- From tough engineering plastics to castable resins, FabPro materials are designed for accuracy and quality. Additionally, our easy-to-load materials enable quick set up and mess-free printing.

- This entry-level powerhouse packs industrial durability and reliability into a rugged yet compact platform, delivering professional quality day in and day out. It's also simple to use – from setup, material loading and file configuration to post-processing, cleaning, and maintenance

- A UV curing unit is required to fully finish your new parts, either in the recommended 3D Systems LC-3DPrint Box, or other UV curing unit. Note that 3D Systems’ materials, curing unit and build process were developed as a set to produce high quality and detailed parts. If you opt to use a non-3D Systems curing unit, we are not able to ensure that your part will meet the mechanical properties specified on our Data Sheet

You must be logged in to post a review.

Reviews

There are no reviews yet.