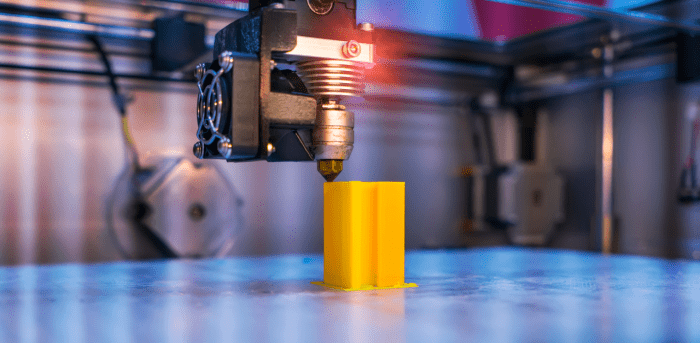

Wipro 3D and Engine Division of Hindustan Aeronautics Ltd (HAL) have collaborated for the development, manufacturing and air-worthiness certification of a critical aero-engine component operating in the hot zone, using metal 3D printing.

.

The Nozzle Guide Vane (also called the Inner Ring), 3D printed in a high-temperature resilient steel A286, has been awarded Airworthiness certification by Centre for Military Airworthiness and Certification (CEMILAC), the regulatory body of Defence Research and Development Organization (DRDO), a Wipro 3D statement said on Tuesday. Wipro 3D is the metal Additive Manufacturing (AM) business of Wipro Infrastructure Engineering (WIN).

.

“The Wipro3D manufactured components shall be installed in HAL manufactured helicopter engines”, the statement said. CEO of Bangalore Complex, HAL, Amitabh Bhatt said Additive Manufacturing is a disruptive technology and is going to play a big role in the manufacture of components used in the Aerospace and Defence Industry in the future. Complimenting Wipro 3D and HAL Engine Division for successfully developing a 3D component for use in the hot section of an aero engine, Bhatt said it is indeed a significant achievement towards “Aatmanirbhar Bharat Policy of Government of India.”

Click here to view original web page at www.deccanherald.com

0 Comments